Plastics like LDPE, or low density polyethylene, are now used all over the world as they are cost-effective and durable. The durable yet flexible material is the pillar of the modern industry due to its extensive use, ranging from packaging food to supermarket bags. In order to achieve a sustainable planet one must understand the extent of what LDPE is and efficient recycling techniques for it. Let us take a look into the world of LDPE plastic material, its properties, uses, and recyclability.

LDPE is a branched, petroleum thermoplastic that is designed to enable maximum flexibility and durability. LDPE is not as dense as its alternative, high-density polyethylene plastic (HDPE), which makes it softer and flexible. The flexibility of LDPE makes it perfect for applications from medical supplies to packaging and recycled plastics.

LDPE products run the gamut from farm film to squeeze containers and fill up every conceivable industry. But widespread use also lends itself to consideration of environmental stewardship and recyclability, topics we’ll take up in this blog. Educating ourselves on ldpe applications and their lifecycle helps us to make informed decisions to reduce waste and encourage sustainability.

Applications of LDPE Plastics

Low density polyethylene plastic material is valued for its flexibility, and it is a first-choice raw material option in many industries. The advantages from the creation of thin, flexible films to having resistance to moderate stress has resulted in various low density polyethylene plastic applications :

Packaging Films

Applied to plastic bags, shrink wraps, and food packaging because of their clarity and flexibility.

Containers

Squeeze bottles, lids, and caps are enhanced by LDPE’s soft but strong quality.

Agricultural Films

Greenhouse covers and mulch films depend on LDPE for weather protection.

Pipes and Fittings

Irrigation pipes and flexible tubing utilize LDPE due to corrosion resistance.

Consumer Goods

LDPE products are used in toys, household wraps, and paper carton coatings.

Properties of LDPE

The properties of low-density polyethylene (ldpe) plastic are a result of the molecular structure, which enables it to find a balance between strength and flexibility.

Flexibility

The chain structure of LDPE plastic makes it best suited for films and pouches.

Chemical Resistance

Lasts long in harsh environments as it has resistance towards acids, bases, and alcohols.

Low Density

Reduces material cost and weight as it is less dense than other plastics.

Transparency

Crystalline structure of LDPE results in transparency and allows for use in the production of transparent packaging.

Moisture Resistance

Extends shelf life for food products and provides moisture protection for packaged products used in the food and pharmaceutical industries.

Recyclability

Most LDPE plastic products can be collected and reprocessed to make new products.

Advantages & Disadvantages of LDPE

Let’s look at the advantages and disadvantages of LDPE, which will determine its applicability for different purposes.

Advantages

Cost Effective

Cheap to manufacture, making recycled LDPE granules an economical raw material option.

Adaptable

Adaptable for use in a variety of products, from films to molded products.

Reusable

Processed into new LDPE products, enabling circular economies.

Lightweight

Lowers shipping costs and energy consumption for manufacturers.

Disadvantages

Lower Strength

LDPE has low tensile strength, limiting it to light-weight applications.

Environmental Issues

Leads to pollution if LDPE plastic material is disposed of inappropriately.

Thermal Sensitivity

Limited applications in heated conditions as it melts at low temperatures.

How to Properly Recycle LDPE

Proper recycling of low density polyethylene is important in minimizing plastic waste and saving resources. This ensures LDPE granules can be recycled effectively.

Collection

LDPE products, such as plastic bags and films are collected by businesses for baling. There are also established distribution centres that lead collections efforts and transport baled products to LDPE recycling centres for sorting and processing.

Processing

At recycling centres, cleaned and sorted LDPE products are shredded, melted, and re-molded into granules for producing new products.

Reuse

Reused LDPE is utilized to produce bags, pipes, etc.

Low Density Polyethylene Examples

Packaging Materials: Plastic bags (shopping, dry cleaning, bread, frozen food), cling wrap, bubble wrap, and protective film.

Containers and Bottles: Squeezable bottles (honey, mustard, soap), flexible food storage containers, and juice/milk carton coatings.

Consumer Goods & Industrial: Garbage bags, flexible pipes, tubing, agricultural greenhouse films, and six-pack rings.

Specialized Uses: Playground slides, artificial limbs (prosthetics), and electrical cable insulation.

Innovations and Future Trends in LDPE

The future of LDPE plastic is evolving with technical and sustainability developments. Technical innovations in the use of LDPE target reducing environmental effects while maintaining performance.

Bio-Based LDPE

Made from renewable resources like sugarcane to reduce the reliance on fossil fuels.

Recycling of LDPE

LDPE is broken down through chemical recycling and mechanical recycling processes into its higher-quality recycled polymers for reuse.

Biodegradable Additives

Research on additives that make LDPE degrade faster is gaining popularity.

Conclusion

Low-density polyethylene (LDPE) is an inexpensive and durable plastic that is used in packaging, agriculture, and pharmaceutical industries. Provided it is treated appropriately, it is non-biodegradable but recyclable, thus ideal for plastic manufacturing firms, but it has environmental risks. While reducing the use of LDPE plastic products is the ultimate goal, there is a shift towards sustainable manufacturing through efficient recycling procedures. The processing of LDPE products like LDPE film have various benefits. Recycling LDPE products and the use of recycled polymers is the shift that all industries require to play their part in contributing to a circular economy.

FAQ's

Can LDPE be recycled?

Yes, LDPE plastic material is recyclable. Plastic bags, films, and other LDPE products can be processed into new materials once properly collected and sorted. Commonly used feedstock for recycling of LDPE plastic material is retrieved from packaging materials such as films, carrier bags and squeeze bottles.

What does LDPE stand for?

LDPE stands for low-density polyethylene, a flexible plastic whose molecules have branches in their structure. LDPE has its uses in packing materials across various industries.

What are some sustainable alternatives to LDPE?

Alternatives include bio-based plastics, compostable polymers, and reusable materials like paper or cloth that reduce usage of LDPE plastic. The recycling of post consumer or post industrial LDPE also plays an important role in sustainability for brands and organizations.LDPE products produced with the use of recycled LDPE plastic granules are now seen in the production of grocery bags, trash bags and packing films.

To learn more about plastic granules and their types, read: What Are Plastic Granules? Meaning, Types, and Uses

Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

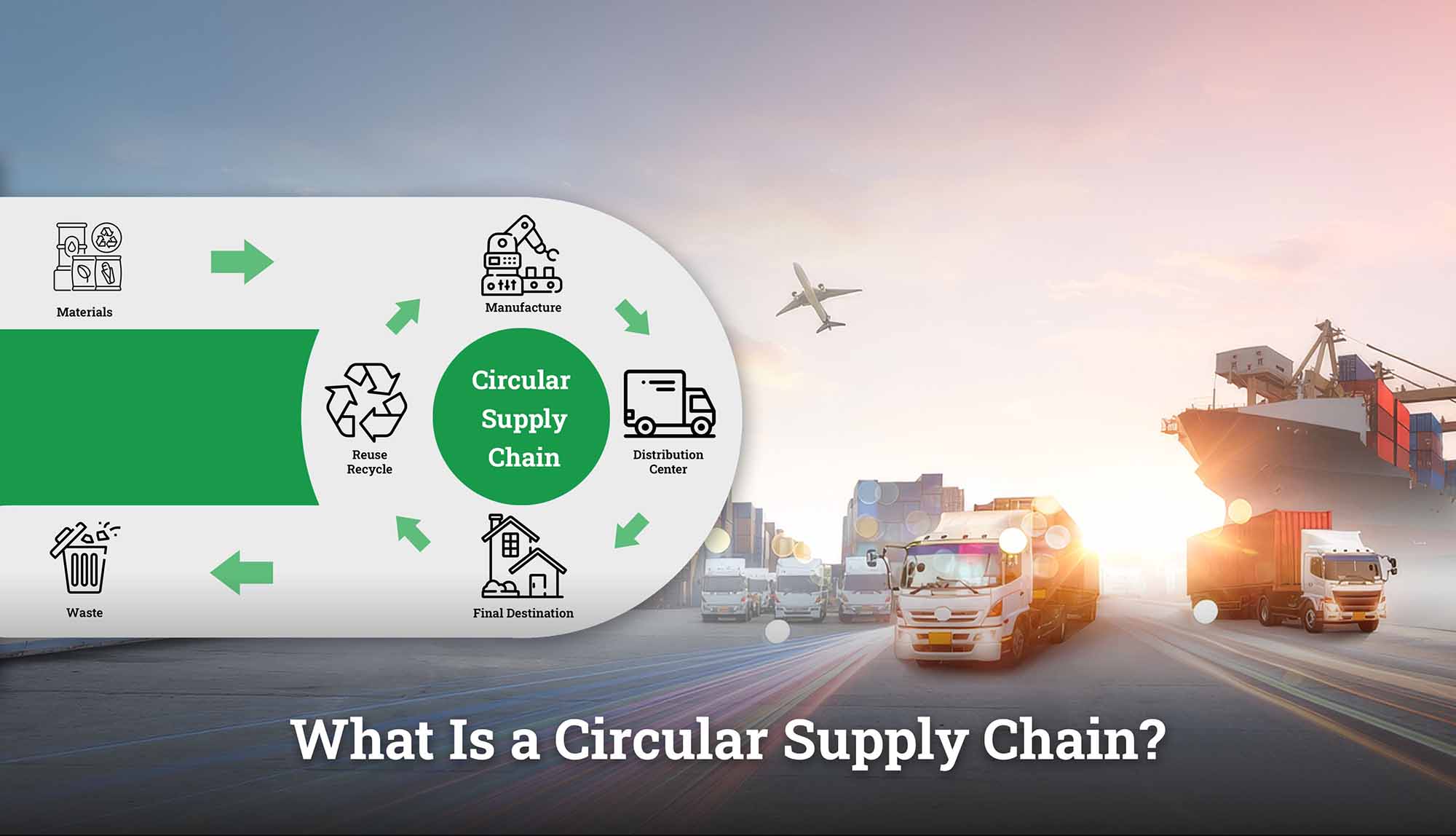

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India? What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling