Modern packaging is built upon materials, which are made of two or more layers of various polymers and usually incorporate such materials as aluminium foil or paper. The issue of multilayer plastic poses a more difficult challenge within the vast problem of plastic waste that the world is facing. The multilayer plastic is designed as a method to provide excellent barrier properties to increase shelf life and food spoilage prevention, which is a paramount requirement in the food-insecure world, especially with chip packets, coffee pouches, and sachets of medicine. Yet, their complexity, as a factor, has always made them non-recyclable by normal mechanical means, pushing billions of tonnes of material into landfill or even worse, it can leak into the environment. Failure to recycle multilayer plastic effectively is a colossal economic and environmental waste that amounts to pollution and directs at the depletion of limited resources. To businesses whose operational objectives and goals are firmly in place in the realm of a circular economy, like Banyan Nation, the multilayer of plastic puzzle is not mere fantasy; it is the future of sustainable management of materials. We should cease to treat these materials as a waste and start treating them as useful feedstock. This paradigm shift needs to be innovative in collection, sorting, and high-tech recycling technology to make sure that all the layers are reclaimed and re-enter the manufacturing supply chain to guarantee the resource efficiency and environment integrity to the following generations.

Introduction

Multi layered plastic is common in our day-to-day lives, and this is usually ignored. It is the quiet workhorse of the consumer goods industry, offering the desired combination of strength, flexibility, and protection. But, this complexity that is required is what makes multi layered plastic one of the main concerns to the recycling industry. Once various polymers are joined together, they cannot be melted and recycled through usual processes which results in a large percentage of our post-consumer waste stream being considered unrecyclable. Overcoming the barrier of multi layered plastic is crucial towards boosting the general recycling rate and bridging the loop of one of the types of materials that is now under high dependence of virgin production. Investment in the technologies required to process multi layered plastic exposes us to a rich pool of material, where waste streams are used to produce high quality secondary raw material.

What are Multi Layer Plastics?

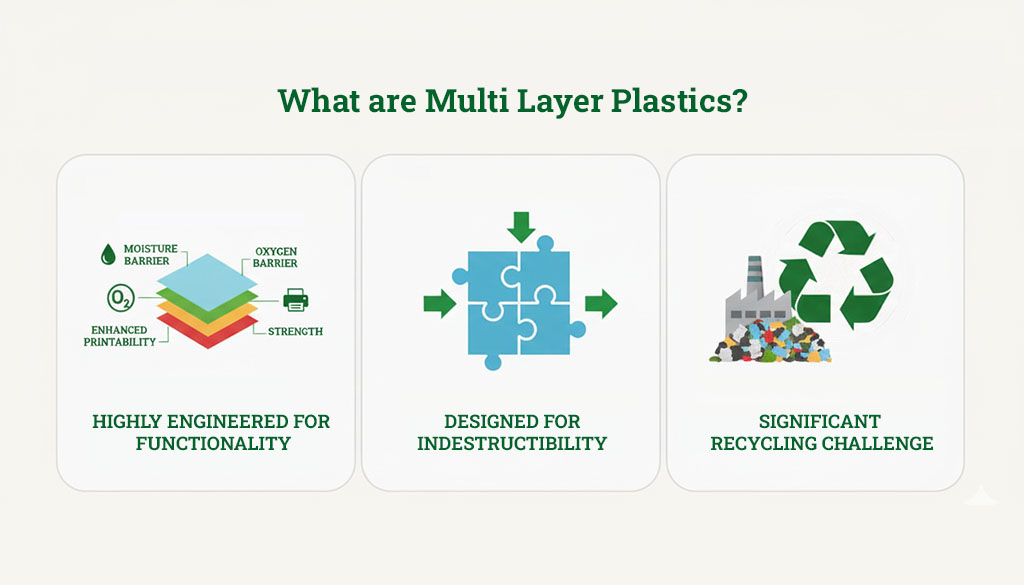

Multi layer plastic is an advanced compound packaging with proper engineering to ensure there is maximum functionality. They are produced by combining several separate layers together, in some cases of up to 12 layers of various materials. Every layer has a distinct and important role, serving as a moisture barrier, oxygen barrier, structural strength, or enhancing printability. This is due to the fact that this careful engineering ensures that multi layer plastic can preserve perishable commodities over an extended period of time compared to mono-material. The problem lies in dismantling this carefully designed material. The layers are normally glued together using very powerful adhesives and thus, cannot be separated by any mechanical means. The property of this structure makes sure that the product is not easily compromised but poses the major challenge to the conventional multi layer plastic reprocessing plants.

Types of Multilayer Plastic

Multi layer plastic recycling should consider the wide variety of combinations of materials available in the market. Each composition determines the nature, usage and, most certainly, the proper method of multi layer plastic recycling.

Some of the typical multi layer plastic recycling feedstock depending on the material make-up are as follows:

Plastic-Plastic Laminates

These are blends of various polymers, e.g. Polyethylene (PE) and Polypropylene (PP), Polyethylene (PE) and Polyamide (PA). Such laminates find application in high strength bags and food pouches. They may be designed to be mono-material-ready with layers of the same polymer family base and this facilitates mechanical recycling.

Plastic-Aluminum-Plastic Laminates

This is applied commonly to snack packets, coffee refills, and liquid packages (e.g. Tetra Pak structure). The layer of aluminium foil is of superior quality in terms of light and oxygen barriers. The mixture of these materials is especially problematic since the aluminum coat has to be separated through complicated procedures.

Plastic-Paper-Aluminum-Plastic Cartons

These are multi layer plastic systems that are rigid and used in the packaging of juices and milk. It takes them a special pulping procedure to extract the paper fibres and to leave behind a plastic-aluminum composite which must be further processed.

Co-Extruded Films

Co-extrusion is applied to certain products such as squeezable tubes of toothpaste, or certain dairy packaging, where multiple polymer melts are extruded simultaneously to create layers that bond together, without adhesives. Although it is technically a multi layer plastic the design may at times be easier to handle than adhesively laminated constructions.

Why Multi Layered Plastics are Hard to Recycle?

The nature of the challenge of recycling multilayer plastic packaging can be explained by the fact that they are designed in a way that makes it more complex. To achieve the circularity of multilayer plastic packaging material stream, the following barriers at the systemic level should be removed.

Material Incompatibility

Multiple polymers (PE, PP, PET, EVOH) can be contained in one single piece of a multi layered plastic with a metallic layer (Aluminum). These layers melt at radically different temperatures and chemically, and so trying to combine them, as in the standard method of mechanical recycling, will create an impure and low-quality material with uneven and low mechanical properties. The resulting mixture usually is fragile and commercially implausible. This material incompatibility is the bane of multilayer plastic packaging.

Adhesive Barrier

The layers in most of the multilayer plastic are bonded with special and powerful adhesive which ensures that the layers do not delaminate (separate) when used in ordinary washing and grinding. These glues are left as pollutants in the end product of the recycled material which also affects the quality of the recycled multi layer plastic.

Contamination and Residue

Multilayer plastic packages are commonly applied in food, sauces, oils, and other residues. The thinness of the film also means that the film can easily retain large amounts of organic contamination even after initial cleaning and this inhibits the multilayer plastic to be processed and reduces the market value of the resultant product.

Sorting Challenges

The sorting facility in place today (MRFs) is mostly based on Near-Infrared (NIR) technology that is not very proficient at recognizing the definite composition of thin and opaque or highly decorated multi layered plastic films, and they are therefore either misdirected or rejected.

Why Multi Layer Plastics are Important to Recycle?

Recycling multilayer packaging is a requirement that is dictated by environmental imperative and economic imperative. Multilayer plastic does not comprise a small portion of the waste stream; it is a large portion of the consumer plastic waste and especially as concerns developing economies.

To begin with, recycling multilayer packaging is paramount in conservation of the environment. By placing this bulky waste out of landfills and the environment, we are proactively eliminating littering, methane gas release through decomposition. Also, controlling the swell of lightweight and readily diffused plastics that are a source of marine pollution. Second, multilayer packaging is a viable economic opportunity to recycle. Considering this waste as a useful second resource, a commodity, not rubbish, we minimize the use of expensive, fossil-intensive production of virgin polymer. This content can be converted into high demand goods, which will establish a strong local market of waste collection and processing that will create sustainable employment and boost the overall supply chain of the circular economy.

How to Recycle Multilayer Plastic?

The efficacious implementation of the multilayer recycling of packaging depends on the innovative processing techniques that overcome the incompatibility of layers.

It has been established that modern recycling of multilayer packaging goes beyond mere mechanical melting and there are three important technological options:

Mechanical Recycling and Upcycling

This means that the MLP is shredded into a flake of composite, and utilized as a substitute raw material in the construction process (e.g. mixed with sand or bitumen to form road construction, or consists of composite planks/tiles). Although it is technically known as downcycling, this method is effective in preventing 100 percent of materials in the landfills.

Solvent-Based Recycling (Delamination)

It is a high-performance recycling technique for multilayer packaging. Other processes such as Solvent-Targeted Recovery and Precipitation (STRAP) or CreaSolv process apply specialized solvents to dissolve a single polymer layer at a time, leaving the others intact. Dissolved polymer can be subsequently precipitated to get pure resin, and the solvent obtained is reused. This can recover a high-quality and pure-grade PE, PP, or PET of the multilayer packaging recycling composite, thus it has become virgin-equivalent.

Chemical Recycling (Pyrolysis)

In the most contaminated or complex MLP streams, it is possible to apply chemical recycling, that is, pyrolysis. This is done through heating the plastic without the presence of oxygen to decompose the polymers into the basic chemical elements (hydrocarbons or oils). These oils could in turn be recycled into feedstocks to new grade virgin plastics, to loop the complex multilayer packaging recycling process close enough.

Future of Multilayer Plastic Recycling

Design for Recyclability and Advanced Separation Technology are two potent concepts that are closely tied to the future of multilayer plastic recycling. Brand owners in a circular world are shifting to the creation of packaging with mono-material laminates i.e. the entire package consists of only one type of polymer as a base (e.g. all PE or all PP). This new technology makes the process of reuse extremely easier and these new generation MLPs become compatible with high-quality mechanical recycling systems. Moreover, the incorporation of Artificial Intelligence (AI) and Machine Learning systems into sorting plants will allow them to recognize even minor variations in MLP composition at the high speed level and deliver cleaner and valuable feedstock to advanced recyclers such as Banyan Nation. Such a combination of smarter design upstream and advanced technology downstream is what would finally make it really possible to achieve true, scalable circularity in multi-layer films.

Conclusion

The difficulty of the multilayer plastic is not an insurmountable obstacle, but it is a design problem the recycling industry is swiftly solving. By using novel methods to upcycle composite flakes through advanced mechanical methods as well as chemical methods to obtain pure resin, we can extract the value in multilayer plastics. This is to develop strong, scalable multi layered plastic collection and processing systems that render recycling all forms of plastic packaging economically viable such that it becomes economical to shift the market towards resource efficiency and not environmental waste.

FAQ's

How to identify multi-layer plastic?

Multi layered plastic is something that is usually difficult to recognize through sight. Usually, MLP is thick, flexible, and sometimes crinkly and stiff (such as a chip bag or a coffee refill pouch) in contrast to easily collapsible mono-material films (such as simple grocery bags). In case the packaging offers a better light, moisture or oxygen barrier, it is highly probable that it is MLP. In most of the developing areas, a flexible film which is not a transparent carry bag is classified and gathered as MLP waste.

What are the materials used in multilayer packaging?

Multilayer plastic is composed of multiple materials layered together, typically including:

- Polyolefins: Polyethylene (PE) or Polypropylene (PP) for strength, sealing, and moisture barrier.

- High-Barrier Polymers: Ethylene Vinyl Alcohol (EVOH) or Polyamide (PA) for an oxygen and aroma barrier.

- Metals: Thin Aluminum foil for total light and oxygen block.

Adhesives: Various binding agents (e.g., polyurethane) to fuse the incompatible layers.

What is an example of a multi layered plastic?

Common examples of multi layered plastic include: snack food bags, toothpaste tubes, refill pouches for detergents and shampoos, flexible cheese packaging, retort pouches for ready-to-eat meals, and beverage cartons (which combine plastic, paperboard, and aluminum). To read more about existing processes on plastic recycling : A Complete Guide on Plastic Recycling Process

Making recycled packaging the norm.

CITATIONS:

- Central Pollution Control Board (CPCB) of India. (2016). Consolidated Guidelines for Segregation, Collection and Disposal of Plastic Waste. Retrieved from https://cpcb.nic.in/uploads/plasticwaste/consolidate_guidelines_for_disposal_of_pw.pdf

- Fraunhofer IVV. (n.d.). Recycling of multilayer packaging. Retrieved from https://www.ivv.fraunhofer.de/en/recycling-environment/recycling-multilayer.html

- Google Patents. (2014). CN104210177A – Multi-layered packaging material. Retrieved from https://patents.google.com/patent/CN104210177A/en

- India Together. (2021). Multi-layer packaging, multiple hurdles. Retrieved from https://indiatogether.org/flexpack-environment

- MDPI (MDPI Polymers). (2022). Multilayer Packaging in a Circular Economy. Retrieved from https://pmc.ncbi.nlm.nih.gov/articles/PMC9103501/

- Plastic Film Recycling. (n.d.). Plastic Film Recycling: Home Page. Retrieved from https://plasticfilmrecycling.org/

- Preprints.org / ResearchGate. (2024). A Comprehensive Review of Recent Challenges, Opportunities, and Future Scenarios of Recycling Multilayer Packaging. Retrieved from https://www.preprints.org/manuscript/202411.1799/v1

- Recycling Today. (n.d.). Multi-layer Packaging Recycling: Challenges and Solutions. Retrieved from https://www.recyclingtoday.org/blogs/news/multi-layer-packaging-recycling-challenges-and-solutions

- Scribd. (n.d.). Recycling of Multilayer Plastic Packaging Material (Referencing STRAP – Solvent-Targeted Recovery and Precipitation). Retrieved from https://www.scribd.com/document/678481610/Recycling-of-multilayer-plastic-packaging-material

- VIE Machinery. (n.d.). Understanding Single-Layer Vs Multi-Layer Plastic Packaging. Retrieved from https://viemachinery.com/understanding-single-layer-vs-multi-layer-plastic-packaging/

- Wikipedia. (n.d.). Multilayered packaging. Retrieved from https://en.wikipedia.org/wiki/Multilayered_packaging

- Wikipedia. (n.d.). Plastic recycling. Retrieved from https://en.wikipedia.org/wiki/Plastic_recycling

How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling Why Burning Plastic Is Unsafe and Recycling Is the Better Solution

Why Burning Plastic Is Unsafe and Recycling Is the Better Solution Why “Design For Recycling” Matters for Companies

Why “Design For Recycling” Matters for Companies Why Soft Plastics Are Problematic & Hard to Recycle

Why Soft Plastics Are Problematic & Hard to Recycle What Is Waste Reporting and Why Does It Matter in Plastic Recycling?

What Is Waste Reporting and Why Does It Matter in Plastic Recycling?