A key building block of the contemporary manufacturing industry and one of the most commonly manufactured synthetic plastic polymers on the planet, polypropylene plastic. Also known as polypropylene or recycling code PP, is a material that is highly popular and commonly used in producing numerous products. This variety of characteristics is due to the peculiar mixture of physical, chemical, and mechanical qualities. It is lightweight, extremely heat-resistant, and unbelievably resistant to the activity of chemical solvents, bases, and acids. The polymerization of propylene monomers leads to the production process that results in a strong, semi-crystalline thermoplastic. This implies that compared to the thermoset plastics, polypropylene plastic is meltable, moldable and can be cooled again without much degradation and hence, a wide range of applications with polypropylene plastic and not to mention it as an essential fact is that polypropylene plastic is recyclable. Since the flexible packaging films and tough automobile parts to the rigid food packaging and the medical supplies, the extreme versatility of the polypropylene plastic has entrenched its fundamental use in almost all industries. It is also resistant to fatigue, which means it can be utilized in ‘living hinges’; thin slices of plastic that can be bent back and forth without breaking, which not many other plastics can do. Moreover, the fact that the production of polypropylene plastic is low and it provides a good processability (it can be easily turned into fibers, films and other forms) makes it continue to dominate in the move towards a circular economy as a major material. The comprehensive knowledge of the polypropylene plastic forms not only a polymer, but an irreplaceable engineering substance that can determine the future and the present of sustainable product design.

Introduction

Polypropylene (PP) belongs to the group of polyolefin (i.e. it is made out of olefin monomers). It is a linear polymer of hydrocarbons, and its chemical composition permits a vast amount of customization at the manufacturing stage to make materials of different levels of rigidity, transparency, and impact toughness. This is the reason why polypropylene has become such a popular substance compared to its traditional alternatives with an acceptable performance and cost efficiency. The common usage of pp also presupposes the efficient system of its end-of-life management where the innovative recycling solutions appear.

Understanding Polypropylene Plastic

Polypropylene plastic, is denoted by resin identification code 5 and has a melting point that typically lies in the range 130 C to 171 C (266 F to 340 F) and is therefore used in hot-filled applications and in hot packaging such as microwaving. It is very strong in tensile properties, and is chemically indifferent, that is, it does not readily combine with other substances. This renders pp to be very ideal in food contact and storing chemicals. It is said to be a rather soft plastic, but has a high degree of stiffness and puncture resistance. The density of pp plastic is very low, unlike other plastics that makes the products lighter and cheaper to transport.

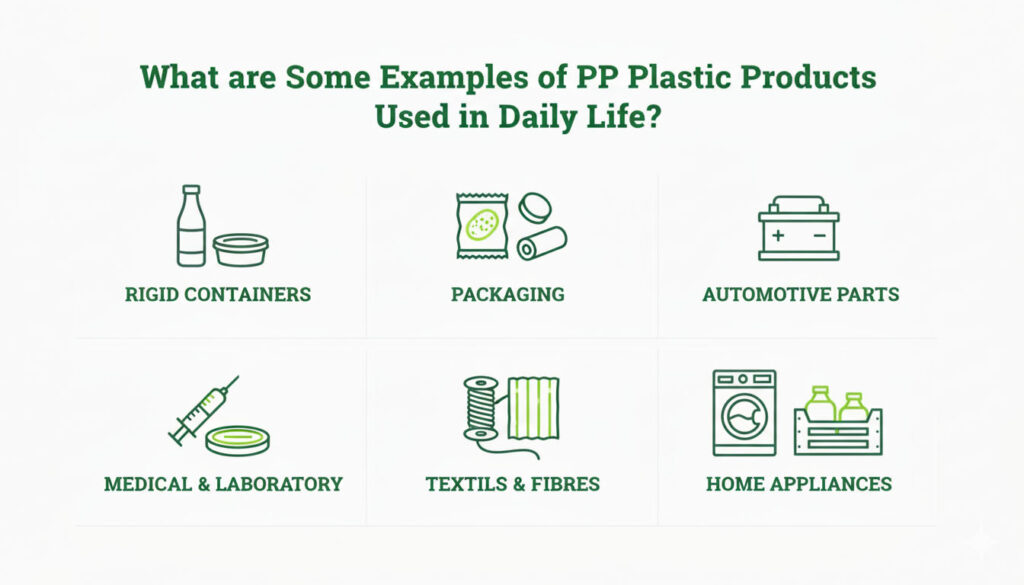

What are Some Examples of PP Plastic Products Used in Daily Life?

Polypropylene plastic is versatile meaning it can be used in a range of pp plastic products. It remains very resistant to fatigue and that is why pp plastic is useful in objects that need to be used on a frequent basis.

Typical pp plastic products and applications are:

Rigid Containers

Yogurt tubs, margarine containers, ketchup containers, and thin wall food containers.

Packaging

Bags (crisp chips), bottle tops and closures, wrap confectionery with using flexible films.

Automotive parts

Car Battery casings, bumpers, interior trim, and dashboard parts because it is impact resistant and is not heavy.

Medical & Laboratory

Syringes, petri dishes and other reusable medical devices which need sterilization because they are resistant against the steam and the heat.

Textiles & Fibres

Rope, carpets, non-woven thermal and non-woven clothing (e.g. disposable masks, hygiene products).

Home appliances

Casing of appliances, crates, storage boxes and polypropylene furniture.

These materials, which are a common usage, are important to recycle efficiently to ensure they do not find their way to the landfills, hence, the real sense of polypropylene in a contemporary economy.

Types of Polypropylene Plastic: Tailoring Performance

The versatile meaning of polypropylene is best illustrated by the breadth of products it enables. It is highly resistant to fatigue, which explains its utility in items requiring repeated use.

Homopolymer Polypropylene (PPH)

This is the commonest general-purpose grade.It is made of propylene monomers only and highly rated in terms of its high strength/weight ratio, great stiffness and good chemical resistance.

Copolymer Polypropylene (PPC)

This kind of polymer contains some small portions (usually 1-7 percent) of ethylene monomers, and may be either randomly distributed throughout the polypropylene chain (random copolymer), or organized into blocks (block copolymer).

Random Copolymers

These are more flexible, optical clarity is higher and impact strength is good even at low temperatures than the homopolymers.

Block Copolymers

These have superior impact resistance at extremely low temperatures and are usually tougher and not as clear as random copolymers.

High-Impact Polypropylene

This is usually realized using compounding or block copolymer which is created in such a way that the material can resist high shock performance without fracturing.

The widespread use makes efficient recycling crucial to prevent these materials from ending up in landfills, thus reinforcing the true meaning of polypropylene in a modern economy.

Applications of Polypropylene Plastic

The use of pp is widespread because of the goodness of polypropylene plastic. Polypropylene is a plastic that has distinctive properties that enable it to fill the gaps between various classes of materials. It can be made stiff like an engineering material, but cheap like a commodity material.

Textile Industry

Polypropylene is a moisture wicking and tough plastic waste material that on spinning is made into fibers and is heavily applied in ropes and technical fabrics.

Packaging Industry

It is a better packaging material against moisture and polypropylene pp plastic is required in the preservation of the freshness of food and extending the shelf life.

Automotive Industry

Polypropylene pp plastic is low-density and high impact strength which makes it reduce the weight of the vehicles in order to increase the fuel economy and safety measures.

Construction

Polypropylene pp plastic is used as pipes, fittings and roofing materials due to its ability to resist corrosion and environmental degradation.

What are the Benefits of Polypropylene Plastic?

The primary benefits are the long service and durability of pp plastic products as well as their safety:

Low Density

It makes it possible to build light products, which will use fewer materials and have lower transportation expenses.

High Melting Point

Enables it to be safe in the microwave and sterilization (autoclaving) which is important in food and medical use.

Chemical Resistance

Polypropylene is a good fat, chemical and moisture barrier and hence can be used in storage and packaging.

Durability and Flexibility

It is able to flex repeatedly (as in a living hinge) without failure, an important functional benefit of polypropylene plastic.

Cost-Effectiveness

It is among the most cost-effective plastic polymers to make.

How Is Polypropylene Plastic Recycled at Banyan Nation?

Recycled polypropylene processing is crucial to the process of recycling due to its high usage. With the help of high-technology, Banyan Nation recycles complex PP waste and transforms it into high-quality recycled granules of pp. We also bypass the difficulties which usually render polypropylene plastic hard to recycle using traditional systems:

High-tech Sorting and Aggregation

We combine with the informal waste market and apply technology to gain a stable and high-quality flow of pp plastic.

Proprietary Cleaning Technology

This is the meat of the process. Our technology is not a typical washing, but rather with proprietary technology to remove contaminants such as inks, labels, oils, and other polymers that usually affect the quality of the recycled polypropylene.

Re-engineering

The resulting PP flakes are extruded and re-engineered to fit exact material requirements so that the resulting recycled pp resin is comparable to virgin resin in terms of quality, consistency of color and performance.

Closed-Loop Supply

Major brands can utilize this high-grade recycled polypropylene to create non-food packs (shampoo and detergent bottles, etc), actually removing the loop on the use of pp plastic products.

Future of Polypropylene in a Circular Economy

Polypropylene is a type of plastic with enormous potential to the circular economy. With the increasing regulatory pressure (e.g., with the implementation of EPR), the demand for high-quality recycled pp will skyrocket and it will become not a waste product, but a high-quality resource. The fact that organisations such as Banyan Nation have managed to manufacture near-viral quality recycled polypropylene continuously implies that brands no longer need to sacrifice the quality of their products in order to meet their sustainability objectives. The industry is trending towards higher standardization and design-to-recycle ideology whereby problematic additives are being eliminated in order to make the best of the recycled pp use and reuse in other products.

Conclusion

Polypropylene is a plastic that is essential in our life. The role it plays as an important recyclable material is also being redefined as the emphasis is altered toward a linear model to a circular one. With improved cleaning and processing, the waste problem is being turned to an advantage of making good quality recycled polypropylene. Through collaboration with innovative polypropylene firms such as Banyan Nation, industries will be in a position to make sure that its dependency on this material of multiple applications is sustainable, as well as environmentally and economically friendly.

FAQ's

Is Polypropylene Plastic Difficult to Recycle?

Historically, yes pp polypropylene has been difficult to recycle. Although technically recyclable, the contamination in the mixed waste stream was high, and the type of polypropylene (films, rigid plastics) varied significantly in the mixed waste stream, thus it was difficult to recycle the polypropylene to high quality. Nonetheless, with the current, advanced cleaning and compounding technologies that have increased the application of polypropylene, employed by advanced polypropylene companies, the production of near-virgin quality recycled pp is now very much achievable.

What products can be made from recycled polypropylene?

Different types of polypropylene plastic can be used in a vast range of products. Some of the examples of polypropylene which are made from recycled polypropylene are non-food consumer packaging (shampoo, detergent, and lubricant bottles), automotive parts (bumpers and interior trim), storage crates, flower pots, and various household and garden furniture.

Is polypropylene a hard or soft plastic?

Polypropylene is generally considered a semi-rigid plastic. It is flexible enough to allow for ‘living hinges’ but stiff enough to form structural containers, offering a versatile middle ground between hard, brittle plastics and very soft, flexible films.

What is the primary advantage of polypropylene plastic?

The primary advantages of polypropylene plastic is its exceptional heat and chemical resistance combined with its low density and the ability to be used for repeatedly flexible parts.

Making recycled packaging the norm.

CITATIONS:

- Plastics Industry Association. (2024). Polypropylene (PP): The Basics. Retrieved from https://www.specialchem.com/plastics/guide/polypropylene-pp-plastic

- The Circular Economy. (2023). Focus on Plastic Recycling. Retrieved from https://www.researchgate.net/publication/370567186_Circularity_in_polymers_addressing_performance_and_sustainability_challenges_using_dynamic_covalent_chemistries

- Smith, J. (2022). Advanced Polymers and the Future of Circularity. Circularity. Retrieved from https://experiments.springernature.com/nature/primers/10.1038/s43586-022-00124-8

- Polyolefins. (2021). Chemical and Physical Properties of Polypropylene. Retrieved from https://www.chemicalbook.com/article/the-physical-and-chemical-properties-of-polypropylene.htm

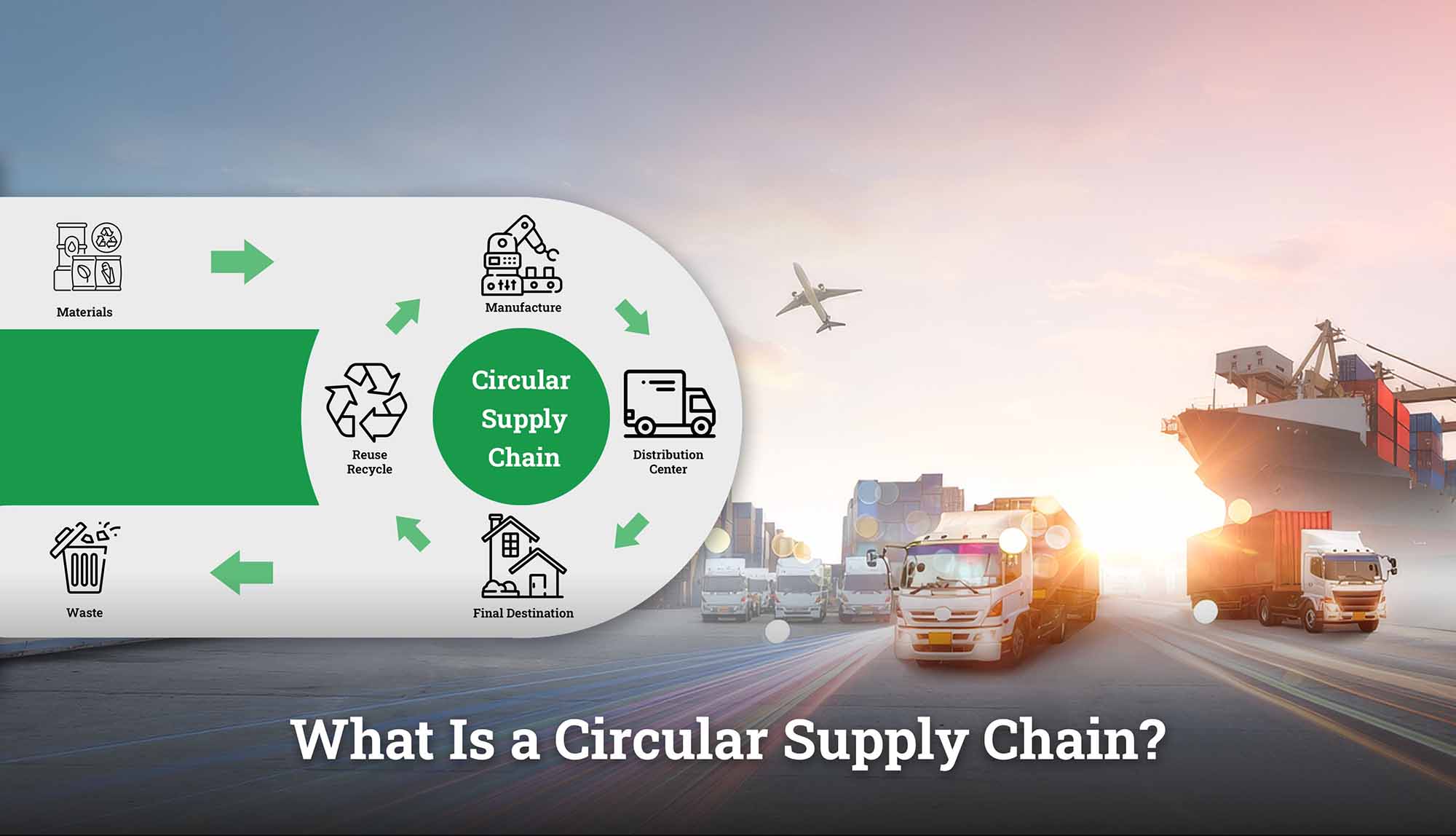

What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

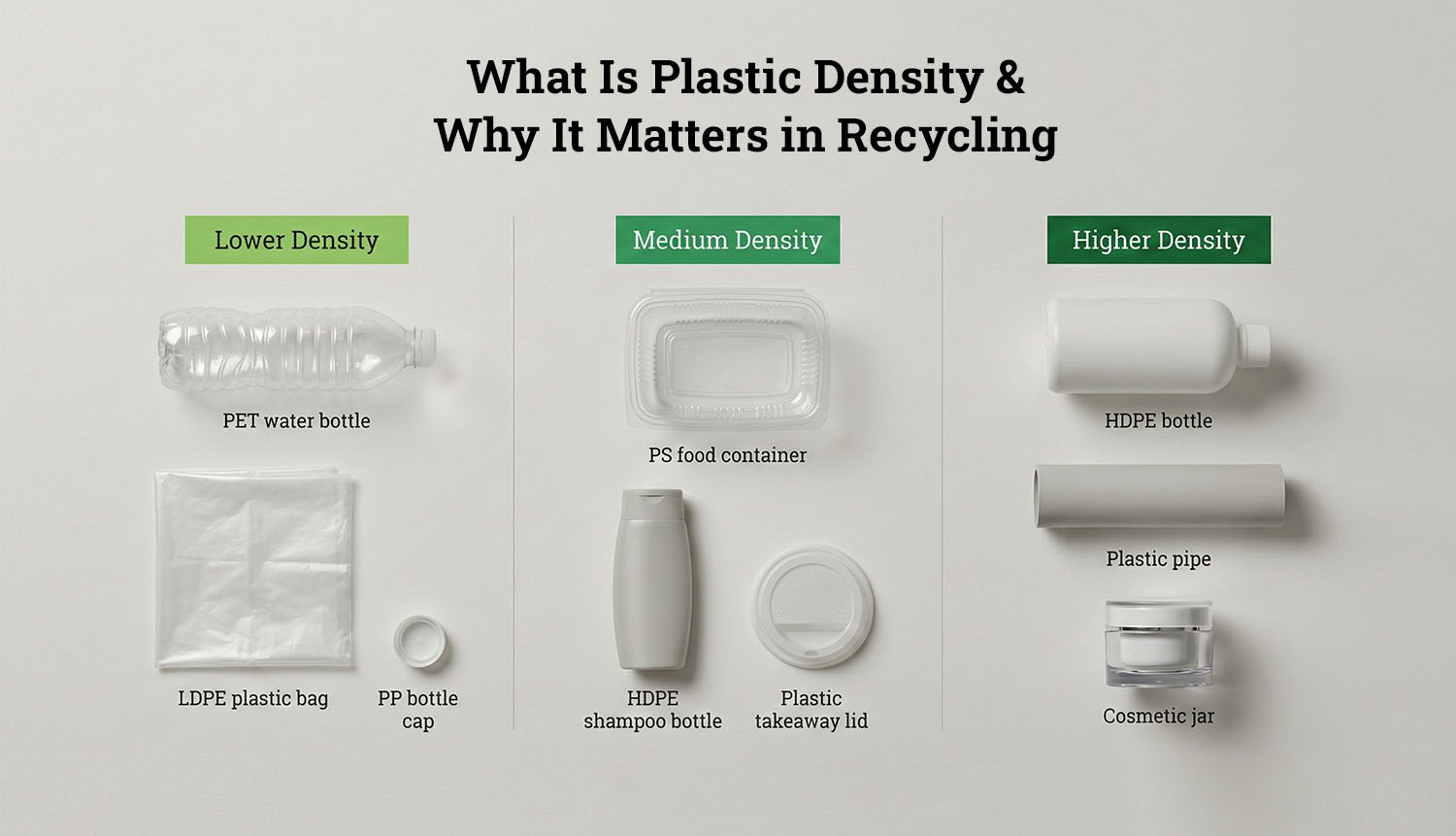

What is the Importance of Recycling in India? What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling Why Burning Plastic Is Unsafe and Recycling Is the Better Solution

Why Burning Plastic Is Unsafe and Recycling Is the Better Solution