The very process of consumption of a drink and disposal of a container in a recycling bin is the first step in an essential process. Nevertheless, over the years, a significant amount of plastic bottle recycling in the world has led to downcycling, the use of a high-quality product into a low-value product, such as the conversion of beverage containers into carpet fibres, or park benches. Although it is better than landfilling, this process does not preserve the original integrity of the material. In the modern world, attention has been directed towards plastic bottle recycling, in particular, the technique of Bottle-to-Bottle Recycling, which guarantees that the material will remain in the same closed circle and maintain high quality necessary to be used for the same purpose. This change is significant to India that is among the largest consumers and collectors of PET plastic that is the main material of the majority of single-use beverage and water bottles in the world. As one of the leaders in the circular economy, India can firmly focus on recycling high-grade plastic bottles instead of just collecting them, but actually transforming them into a different material. This will need the use of sophisticated technologies and supply chains to come up with food-contact-safe recycled plastic to satisfy the high-quality standards of domestic regulators and multinational brands. Moreover, the compulsory measure that the Indian government has imposed on new PET bottles that require a portion of recycled plastic to be included in the bottle has greatly increased the position of plastic bottle recycling as a voluntary activity to a national need so that resources are saved and waste is minimized.

Introduction

India’s already high rate of bottle recycling, largely driven by the efficient informal waste sector, has always been a good secondary stream of material. Nevertheless, to be fully in the circle economy, we should get maximum out of the value of the material by preventing downcycling. Recycling of the bottle should not be focused on ensuring that low-grade material is made to produce textile but rather high-quality resin that can be used to produce new containers of food and beverages. This is the increased level of standard which makes PET, a valuable and durable polymer to be held to the maximum value chain. Such attention to high-quality bottle recycling is necessary to satisfy the rising expectations of the consumer-based goods brands that attach importance in the world to the recycling of the increase in the level of recycled content in the packaging.

What Is Bottle-to-Bottle Recycling?

Another technique used to recycle plastic bottles is bottle-to-bottle recycling, where the post-consumer bottles are collected, carefully washed, and recycles into a recycled resin that is safe and performing well enough to be recycled back into food-grade bottles again. The closed-loop system is very technical in contrast to simple recycling where the goal is to regain the integrity of the polymer to almost virgin quality. PET (Polyethylene Terephthalate) is normally the material of choice in this process. This choice means less consumption of energy, less use of finite fossil fuels and the problem of waste is directly solved since the high-quality polymer is not contaminated by the bottles that have been closed with the goal of recycling the plastic materials. This is the benchmark of circularity in the packaging industry.

How Plastic Bottle Recycling Works?

Bottles for recycling into new bottles is a complex industrial process and involves precision and advanced technologies. The procedures are important in the elimination of all contaminants, odors, and colors, which is vital towards ensuring food-grade safety:

Collection and Sorting

Post-consumer PET bottles for recycling are gathered (usually through the informal sector in India) and sorted to take off those that are not plastic (HDPE, PP, etc.) and the non-plastic waste.

Baling and Transportation

Sorted bottles are pressed in huge bales to be easily transported to the recycling plant. Washing and Cleaning: This is a very important step, which is to grind the bottles into flakes and then subjected to intensive hot-wash to take off the labels, adhesives and remnants.

Purification and Extrusion

The flakes are melted, filtered to eliminate microscopic impurities and extruded into tiny pellets, called rPET (recycled PET).

Solid State Polymerization (SSP)

When it reaches this stage, the intrinsic viscosity (molecular weight) of the polymer is once again raised to a food-grade level, which is now ready to be reinvested back into preforms of new bottles.

The intensity with which it is done at every step determines the answer to how plastic bottles can be recycled as high-quality containers that are safe, instead of low-grade materials.

What are the Benefits of Recycling Bottles?

Bottles for recycling using the Bottle-to-Bottle process has significant benefits and the advantages of this approach lie not only in the factory floor but also in the climate of the world at large:

Massive Powersaving

rPET production consumes up to 75 percent less energy than virgin PET production out of crude oil (TERI, 2022), resulting in lower greenhouse gases.

Resource Conservation

Every recycled bottle is saving precious resources of petroleum that are not necessarily used to be dependent on fossil fuel.

Less Landfill Volume

Recycling plastic bottles will also result in millions of tons of recycling waste that will not be added to landfills and the lakes, and this will lessen the pollution in the environment.

Value Retention

This process unlike downcycling maintains a high material value of the polymer, which forms a more economically sound circular economy.

Recycling of bottles is a strategy that should not be ignored by the corporate sustainability agenda and national management of resources due to its cumulative benefits.

Different Types of Plastic Bottles Used in Recycling

Although it is true that we currently use numerous plastic bottles types, not all of them can be recycled as Bottle-to-Bottle. PET (Polyethylene Terephthalate) with the Resin Identification Code (RIC) #1 is the main type of plastic bottle that will be used. To understand how can we recycle plastic bottles, let’s explore.:

PET (RIC #1)

That is used in water, soft drinks, and some food containers. It is the most recycled and high-grade plastic bottle types are in the direction of the high-grade plastic bottle recovery as it is pure and food-grade.

HDPE (RIC #2)

Applied to milk and juice, rigid bottles of cleaners. It is very easily recyclable, but is commonly recycled into non-food containers or industrial goods (e.g. pipes).

PVC (RIC #3), LDPE (RIC #4), PP (RIC #5), PS (RIC #6), and Others (RIC #7)

These are the types of plastic bottles which are utilized in other rigid as well as flexible packaging formats but are not utilized in Bottle-to-Bottle foods because of the complexities in the processing or because of the possibility of contamination.

It is the clarity and the high value of the PET stream, which makes Bottle-to-Bottle Recycling economical and technically achievable for plastic bottles types.

Why Bottle-to-Bottle Recycling Matters for India

Bottle-to-Bottle Recycling is a game changer on how can we recycle plastic bottles to India because of the regulatory and economical implications.

To begin with, the Plastic Waste Management Rules in India, 2022, and its later requirements, demand that brand owners have an increasing proportion of recycled material in their packaging. This is aimed at 30 percent of recycled content in PET bottles by 2025 that offers a massive and steady market with high-quality recycled material (The Better India, 2025). This institutional requirement is the impetus of the whole supply chain.

Secondly, it has one of the most efficient plastic bottle recycling systems in the world in part because of the informal system of waste pickers, with a PET recovery rate that is estimated to be approximately 95% (CPCB, 2022). To a large extent this has been downcycled however. The Recycling Bottle-to-Bottle is more economically efficient, as it ensures maximum profit of the collected material and formalizes and stabilizes the income of thousands of waste workers in the collection ecosystem. This advances the Indian recycling process to the global food-grade safety standards.

How Banyan Nation Is Transforming Bottle-to-Bottle Recycling in India

Banyan Nation is perfectly placed to expedite the implementation of high-quality Bottle-to-Bottle Recycling in India, especially of polyolefins (rHDPE and rPP) used in bottles of non-beverage FMCG products (such as shampoos and detergents), and more so in food grade uses (Banyan Nation, 2025).

Proprietary Cleaning Technology

Our futuristic, patented clean and wash process has removed more than 98 percent of contaminants, body smells and volatile organic compounds (VOCs). This is essential in order to cover the strict food and human-contact safety criteria involved in the Bottle-to-Bottle Recycling.

Traceability and Transparency

We use data intelligence platform, which follows waste since it is collected to the final recycled pellet. This traceability can be verified and will be critical to brands that require traceability of compliance to be audit-proof and that their recycled content is ethically sourced and actually closed-loop.

High-Quality Product

Banyan Nation manufactures recycled resins (rPE and rPP) that can be considered as identical in terms of their performance qualities as virgin plastic, allowing such brands as Unilever and Reckitt to comfortably use our material in the main pack, a genuine use of Bottle-to-Bottle Recycling.

The Future of Bottle-to-Bottle Recycling in India

The future of the Bottle-to-Bottle Recycling in India is technologically high and bright. The need to have traceable, food-grade rPET and rHDPE will only rise as the regulations become stricter and consumers become more aware. This will stimulate the further investment in new sorting technologies and chemical recycling to address the streams of plastic bottle can that are hard to recycle. The bulk is delivered by the informal system of collection that is large and efficient in India and the quality assurance is offered by the technology pioneers. It is hoped that Bottle-to-Bottle Recycling will be the new status of all plastic containers, guaranteeing a source of material resources to the generations ahead.

FAQ's

Which Colour-code dustbin is used for plastic bottles?

In India, the most commonly used color-code dustbin for dry recyclable waste, including plastic bottles, is Blue. However, source segregation by material type (PET, HDPE, etc.) is the most effective practice for plastic bottle can be recycled.

What plastic bottles should not be reused?

Bottles that should not be repeatedly reused or heated include those containing the #3 (PVC) and #6 (PS) plastic resins, as they may leach chemicals under stress. Is plastic bottles recyclable? Yes, the vast majority, particularly PET (#1) and HDPE (#2), are highly recyclable.

What type of plastic bottles are 100% recycled?

While technically no plastic is recycled 100% of the time, PET bottles are often cited as the most successfully recycled material globally. In India, the PET recovery rate is already near 95% because of plastic bottle recycling bin. When processed through Bottle-to-Bottle Recycling, the resulting resin is functionally 100% closed-loop.

What are the benefits of recycling bottles?

The benefits of recycling bottles include significant energy conservation (up to 75% compared to virgin plastic), reduced greenhouse gas emissions, decreased landfill waste, and the creation of valuable, high-quality material streams for manufacturing.

Making recycled packaging the norm.

CITATIONS:

- CPCB (Central Pollution Control Board). (2022). Extended Producer Responsibility Guidelines for Plastic Packaging. Retrieved from: https://cpcb.nic.in/

- The Better India. (2025). India’s 2025 PET Bottle Rule: How 30% Recycled Plastic Could Transform the Future. Retrieved from: https://www.thebetterindia.com/444327/india-pet-bottle-recycling-rule-2025/

- The Energy and Resources Institute (TERI). (2022). [Study on Energy Savings in PET Recycling in India.] (General industry estimate; specific link may require database access.)

- Wikipedia. (n.d.). PET bottle recycling. Retrieved from: https://en.wikipedia.org/wiki/PET_bottle_recycling

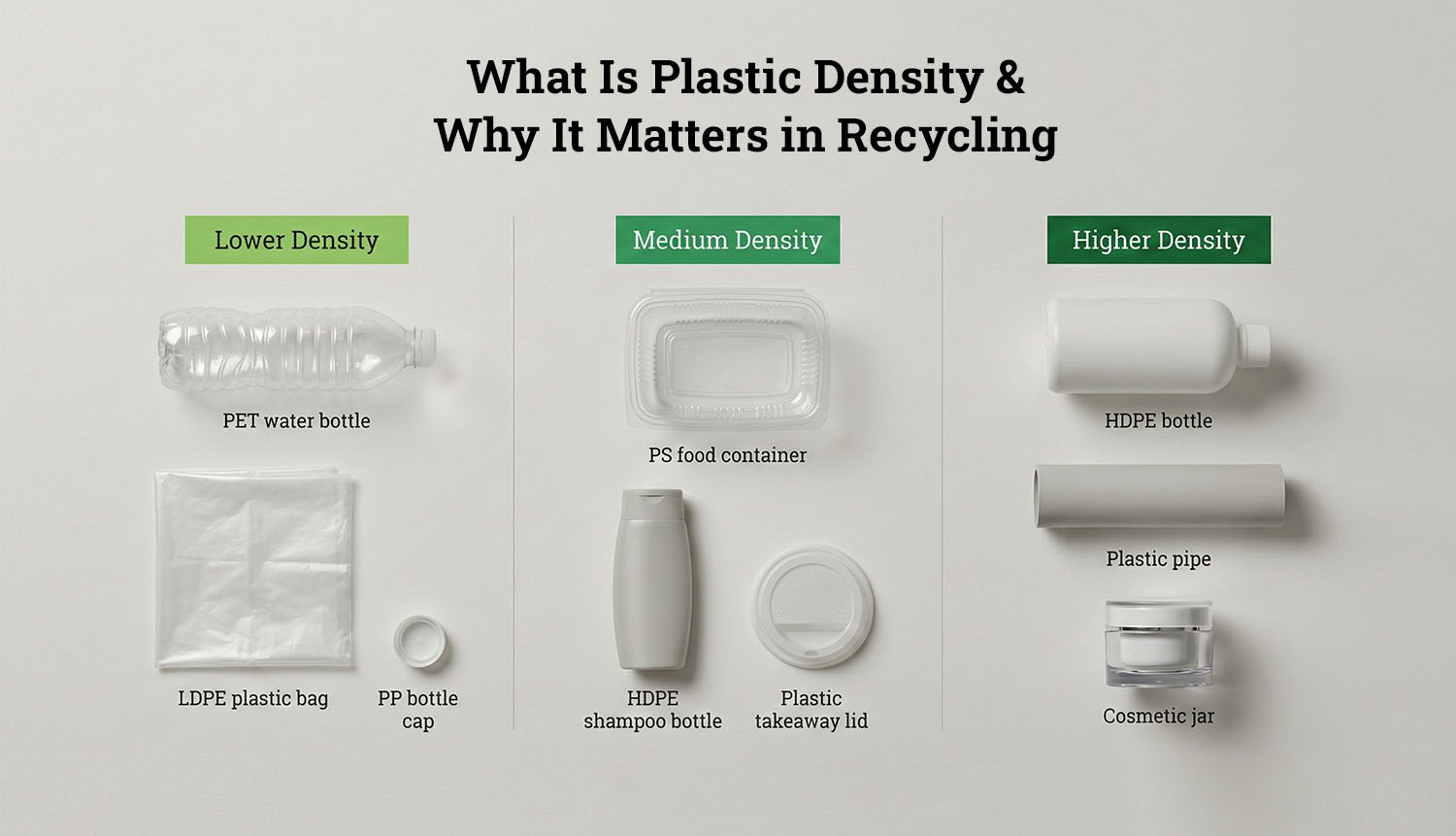

What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling Why Burning Plastic Is Unsafe and Recycling Is the Better Solution

Why Burning Plastic Is Unsafe and Recycling Is the Better Solution Why “Design For Recycling” Matters for Companies

Why “Design For Recycling” Matters for Companies Why Soft Plastics Are Problematic & Hard to Recycle

Why Soft Plastics Are Problematic & Hard to Recycle