The use of plastic in our everyday life has become extremely prominent and unavoidable, from its use in food packaging to homecare products to medical supply. Each used plastic product is often made from different types of thermoplastics. Thermoplastics are a top choice in the packaging sector due to their characteristics of being able to heat, reform and recycle the plastics. Among thermoplastics are two commonly used types called High Density Polyethylene (HDPE) and Low Density Polyethylene (LDPE). The choice of material between both is often dependent on the application for which it is being used. HDPE and HDPE plastics are also categorised under the polyolefins group of polymers.

Applications of LDPE and HDPE plastic vary in durability and application. Exploring the key differences between LDPE and HDPE, recycling codes and choosing the right plastic is important in the manufacturing sector. Both LDPE and HDPE have unique properties and uses and understanding the difference between LDPE and HDPE will help producers choose the right type as per the product and application.

What is HDPE & LDPE Plastics?

HPDE and LDPE plastics are two polymers that play a significant role in industrial applications and make them vital materials. The difference in the physical characteristics between high density polyethylene and low density polyethylene plays a major role in the applications and its selection.

LDPE is a branched, petroleum thermoplastic that is designed to enable maximum flexibility and durability. The flexibility of LDPE makes it perfect for applications from medical supplies to packaging and recycled plastics. HDPE is one of the most versatile and widely used plastics around the world, with known strengths and durability, coupled with its resistance to moisture. It is a thermoplastic based on petroleum and has a specific molecular structure that gives it a high strength-to-density ratio. HDPE has a much lower level of branching compared to LDPE. The difference between high density and low density polyethylene can also be identified through the plastic resin code identification system, HPDE is categorized as #2 and LDPE as #4. These resin codes serve as an important role in the plastic waste management system.

Examples of HDPE & LDPE Plastics

Some of hdpe and ldpe examples include thermoplastics used in our daily life and seen all around us. Common examples of high density polyethylene applications include shampoo bottles, toys, chemical containers, pipe systems, grocery bags, cereal, flower pots.

Common examples of LDPE applications include plastic bags, plastic wraps , water bottles, pipers and squeeze bottles. LDPE also serves the purpose of creating a corrosion protection layer for a few work surfaces.

Recycling Codes of HDPE & LDPE Plastics

Recycling codes of HDPE, LDPE plastics are part of a unique identification system indicating the recyclability of a product. The resin codes are often characterised by 3 chasing arrows with a number in between.

The recycling code of HDPE LDPE plastics are as follows:

1.High Density Polyethylene(HDPE): #2

2.Low Density Polyethylene(LDPE ): #4

Major Differences Between HDPE & LDPE Plastics

HDPE and LDPE differences lie in the characteristics, its uses and its molecular structure. LDPE is not as dense as high density polyethylene (HDPE), which makes it softer and flexible. The Major HDPE and LDPE differences lie in the distinct physical characteristics, its uses, recyclability and molecular structure.

HDPE and LDPE difference in physical characteristics:

| Property | HDPE (High-Density Polyethylene) | LDPE (Low-Density Polyethylene) |

|---|---|---|

| Density | High | Low |

| Rigidity & Durability | Rigid and durable | Softer and flexible |

| Melting Point | ~130–137°C | ~105–115°C |

| Crystallinity | High crystallinity – gives better rigidity | Low crystallinity – increases flexibility |

| Impact Resistance | High impact strength | Moderate impact strength |

| Transparency | Opaque | Transparent or translucent |

| Chemical Resistance | Good | Excellent |

| Recyclability | Easier to recycle | More difficult; requires cleaning and sorting |

| Common Uses | Milk jugs, detergent bottles, pipes | Plastic bags, squeeze bottles, cling film |

The HDPE and LDPE difference is also seen in recyclability:

HDPE and LDPE are both recyclable. The approach and process used for recycling of each varies. HDPE is often considered easier to recycle compared to LDPE. LDPE often involves cleaning to remove contaminants and sorting to ensure it does not get stuck in the processing machinery.

LDPE vs HDPE: Which One Should You Choose for Your Specific Needs?

Depending on the product requirement and the application of the product, the choice can be made with the consideration of HDPE and LDPE differences in terms of physical characteristics, usage allows for selection of the specific needs.

For products requiring a soft and transparent application LDPE can be selected. These could include applications of plastic bags , packaging materials like shrink wraps or squeeze bottles. For applications requiring rigidity and durability with a resistance to chemicals, HDPE plastic polymers can be considered. The products for this can include detergent bottles or pipes or fittings.

Conclusion

The applications of LDPE and HDPE are endless. For manufacturing industries, the options of choosing the right material can become a daunting task. While HDPE offers rigidity and strength for applications like containers and pipers, LDPE provides flexibility suited for applications like bags and films. Recycling of LDPE and HDPE plastics used in the packaging industry play a crucial role in sustainability for businesses. Business investing in sustainable product innovation and green technologies are better positioned in the long term. Understanding the properties of each, their environmental impact and recyclability can help manufacturers as well as consumers make smart choices.

FAQ's

Why is HDPE tougher than LDPE?

HDPE has a linear structure making its uses applicable for a wide range of applications. LDPE and HDPE uses vary significantly owing to their structure. HDPE has a high tensile strength allowing it to resist external strength. LDPE’s branched structure makes it suitable for applications like films and wraps.

LDPE vs HDPE: Which Plastic is more Eco-friendly?

Both plastic polymers can be considered as Eco-friendly due to their ability to be recycled.

Which material is more cost-effective: LDPE or HDPE?

Based on HDPE and LDPE properties, LDPE can often be more cost effective to HDPE. The lower density property contributes to lower transportation charges and production of HDPE can often require more energy leading to higher costs.

Is HDPE easier to recycle than LDPE?

HDPE is marked with a recycling symbol 2 and has a high recyclability potential. HDPE’s rigid structure allows for easier processing at recycling facilities. LDPE characterised by being flexible in nature can often get tangled in recycling machinery.

Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

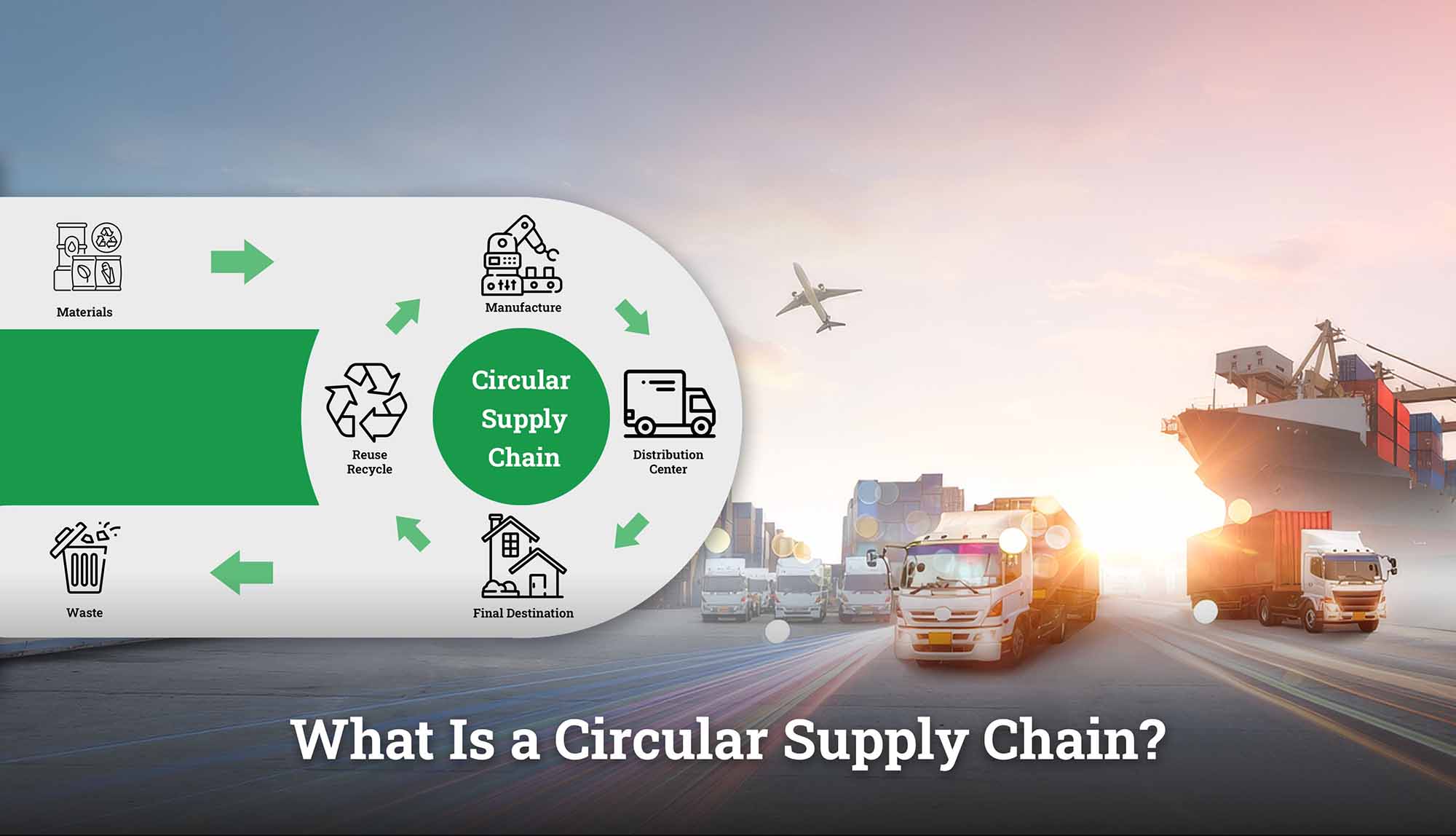

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India? What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling