Circular economy’s success is often dependent upon the presence of properties that are not visible to the naked eye, however they are essential with regard to the manner in which materials behave during recovery. The most important of these is plastic density, which is arguably one of the most important physical properties to ascertain the purity of the recycled resins. A skill to differentiate a PET bottle and its HDPE cap is not, in the convoluted world of waste management, something that can be observed visually but rather it is something that can be explained using geometry. Plastic density is most easily understood as the weight of the material per unit volume, but in the application in industrial recycling, it serves as a molecular fingerprint, which can be separated rapidly and automatically. Recycling would not enjoy a high contamination rate without an in-depth perception of this property since even a minute amount of the incorrect polymer will contaminate a lot of a high-quality PCR (Post-Consumer Recycled) resin. Recent plants utilize the density of different plastics to use sink-float tanks, wherein water or some special liquid serves as the medium to sort materials by their heaviness or lightness compared to the medium. It is this accuracy that enables the plastic density to become the foundation of the mission to improve plastics at Banyan Nation through the “Better Plastic™”. By mastering a perfect command of the science of the behavior of various polymers under different conditions, it is possible to convert mixed waste into high-performance high-equivalent materials that could be used by brands as primary packaging materials.

Introduction

In the quest to achieve sustainable packaging, firms should go beyond the resin identification code and explore technical specifications that govern the material recovery. Density of plastic is the unsung hero of the sorting process which offers a sure method to sort materials which could otherwise be the same to the human sorters or simple sensors.

Knowing the density of plastic enables the recyclers to develop efficient and scalable systems. This property dictates:

- The handling of materials within the flotation tanks.

- The air classification system settings of MRFs ( Material Recovery Facilities).

- The ultimate mechanical characteristics of the resin pellets which are recycled.

What is Plastic Density?

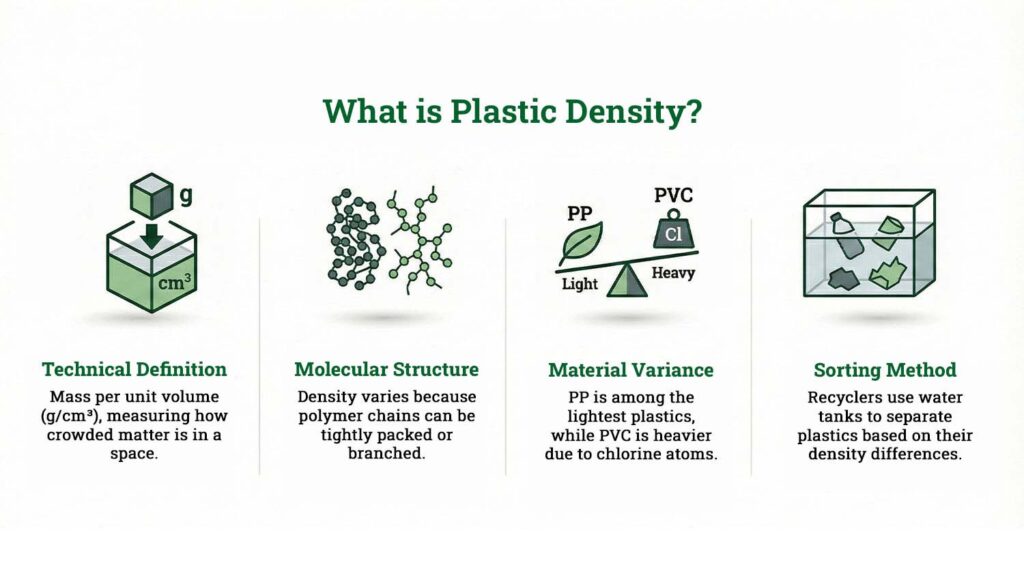

Density of a material in technical terms is the weight of the material (m)/volume of the material (V). This is normally expressed in grams per cubic centimeter (g/cm 3) in the plastics industry. Due to the fact that all polymers are constructed of varying molecular chains some tightly packed and others branched, they all have a distinct all plastic material density profile.

When we refer to the density of plastic, we are actually referring to the amount of stuff that is crowded in to a certain space. Indicatively, Polypropylene (PP) has been identified to be among the lightest plastic whereas Polyvinyl Chloride (PVC) weighs much more because it contains chlorine atoms. It is this core difference that can enable a recycler to apply very simple tank of water to extract the two.

Importance of Plastic Density

In recycling, the plastic density is the most important measure that can be applied to prove the quality and purity of a given material stream. In the absence of proper plastic material density chart and date, the recycling process would be full of mistakes resulting in downcycling or landfilling of good resources.

The significance of plastic density can be subdivided into some main areas:

Material Identification

It offers an infallible method of identification of the resin type in case there is no label, or the label becomes illegible.

Contamination Control

It makes sure that sinker plastics (such as PET) are not contaminated with floater ones (such as PE), otherwise it would lead to failure in the remaining manufacturing process.

Sorting Efficiency

Recycling processes are possible at a high-speed plastic density and thousands of kilograms per hour can be processed with minimum human effort.

Structural Integrity

To manufacturers, the mass, intensity and thickness of the new wall of any new packaging is directly related to the density of the received PCR resin.

All Plastic Material Density Chart

Engineers use a complete plastic material density chart to calibrate their machines in order to cope with waste streams. These values are the standard range of virgin resins but additives and fillers may slightly change these values.

Any facility that is interested in producing high-purity output must use a plastic material density chart. The table below provides an overview of the most widespread polymers and their behavior when used in a basic water-based separation system:

Resin ID | Material Name | Approx. Density (g/cm3) | Behavior in Water (1.00g/cm3) |

1 | PET (Polyethylene Terephthalate) | 1.38 – 1.40 | Sinks |

2 | HDPE (High-Density Polyethylene) | 0.94 – 0.97 | Floats |

3 | PVC (Polyvinyl Chloride) | 1.30 – 1.45 | Sinks |

4 | LDPE (Low-Density Polyethylene) | 0.91 – 0.93 | Floats |

5 | PP (Polypropylene) | 0.90 – 0.92 | Floats |

6 | PS (Polystyrene) | 1.04 – 1.10 | Sinks |

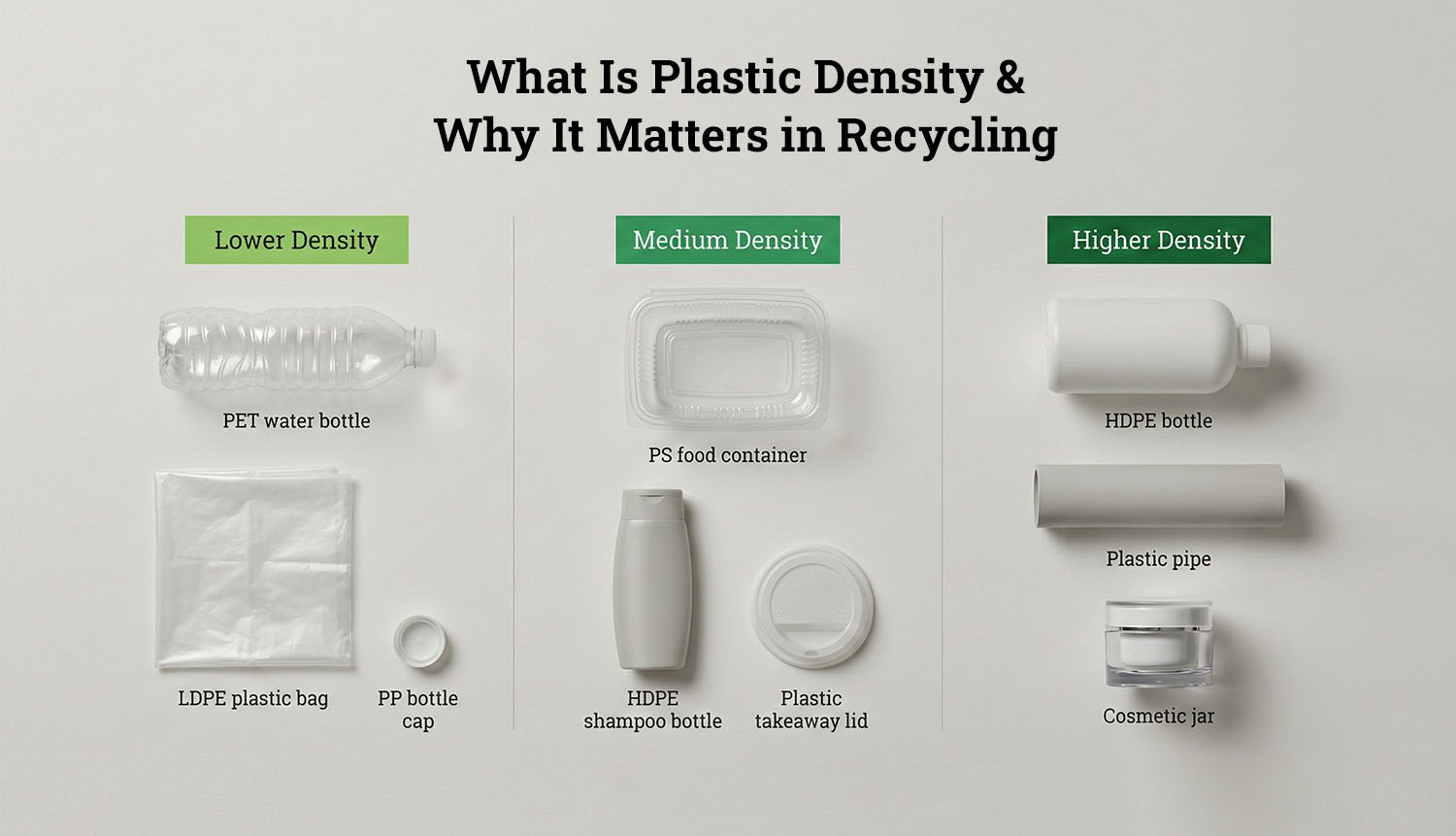

This plastic density chart on the density of plastic material underscores the reasons why water is a very good sorting medium. Plastics such as PP and HDPE will naturally rise on the surface whereas PET and PVC will sink to be separated mechanically in a clean way. The initial step in designing a reliable recovery line is the knowing of all the plastic material density values through a plastic density chart.

How to Calculate Density of Plastic

As a quality control, it may be required to test a load of material on site. Density of plastic is one of the standard requirements of lab technicians in recycling industries along with the help of a plastic density chart.

The most frequent one is the Displacement Method (which is based on the Archimedean Principle):

- Measure Mass: The dry plastic sample must be massed using a precision scale to obtain $m.

- Measure Volume: Place the sample in a graduated cylinder whose volume is known to contain a given volume of water. The alteration in water level is the volume of plastic denoted by V.

- Find Formula: The result is obtained by applying the formula: $\rho = \frac{m/ V.

Density of plastic is crucial to learn how to make decisions that will determine whether it has heavy fillers or a lot of moisture that could have been absorbed during the waste collection stage.

Why Density Based Plastic Sorting Matters in Recycling

Recycling by the use of plastic density is seen most in the Float-Sink tank. This is a huge industrial vat in which flakes of plastic are shredded and swirled in water. Since the density of the plastic material, which is to be recycled, is so different in the bottle bodies (PET) compared to that of the bottle caps (HDPE), the bodies naturally separate in the tank.

This is done so that the PET flakes reaching the extruder would not be contaminated with polyolefins since this would form weak points of the new bottle. The use of these physical laws will guarantee that the resulting PCR will be consistent to be reused in the high demand FMCG packaging.

Impact of Density on Recycling Process

Plastic density in recycling may occasionally have slightly different density than virgin plastic because of the presence of inks, adhesives or multiple heat cycles, which interfere with and modify crystallinity of the polymer. The quality assurance at Banyan Nation includes monitoring of the plastic density in recycling.

In case the concentration of a batch of rHDPE is excessive it can tell that the material has mineral fillers or contains PVC. On the other hand, decreased density could indicate pinacolone between the polymer chains or foaming of the polymer. It is the consistency in the density of recycled plastic that enables our partners to replace virgin resin by our Better Plastic 2018 without re-engineering their complete production line.

Conclusion

Recycling is just a separation game, and the game rules are the plastic density. Since we start sorting on the MRF and continue to sort on our lab, it is the knowledge of the all plastic material density that helps us transform a mountain of mixed materials to a stream of usable resources. Through the strictest plastic density chart and advanced sorting technologies, we overcome the border between what is considered as waste and what is considered as commodity. With the future of 2026 and beyond in sight, the accuracy of density-based sorting will even be more of a necessity as we attempt to seal the loop on any of the most complex flexible packaging and rigid packaging.

FAQ's

What is the Approx Density of Recycled Plastic?

The density of recycled plastic usually mirrors its virgin counterpart very closely. For example, recycled HDPE (rHDPE) typically falls between 0.94 and 0.97 g/cm³, while recycled PET (rPET) stays around 1.38 to 1.40 g/cm³. Minor variations can occur depending on the number of times the material has been heat-processed.

Do Plastics have High Density or Low Density?

Most common packaging plastics are considered low-density compared to metals or glass. Polypropylene and Polyethylene are even lower density than water, which is why they float. However, engineering plastics like PVC and PET are considered “high density” within the polymer family because they sink in water.

What is the highest density plastic?

Among common commodity plastics, PVC (Polyvinyl Chloride) and PET are the densest. In the world of high-performance engineering plastics, materials like PTFE (Teflon) can have a density as high as 2.2 g/cm³, which is more than double the density of water.

Is high density plastic recyclable?

Yes. High-Density Polyethylene (HDPE) is one of the most widely recycled plastics in the world. Its high strength-to-density ratio and linear structure make it ideal for mechanical recycling, allowing it to be turned back into detergent bottles, pipes, and crates multiple times.

Making recycled packaging the norm.

CITATIONS:

- ASTM International. (2025).

Standard Test Method for Density and Specific Gravity of Plastics by Displacement (ASTM D792). - Association of Plastic Recyclers (APR). (2025).

Density Separation Technologies in Plastic Recycling. - Omnexus. (2024).

Comprehensive Guide to Polymer Density and Specific Gravity.

What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling Why Burning Plastic Is Unsafe and Recycling Is the Better Solution

Why Burning Plastic Is Unsafe and Recycling Is the Better Solution Why “Design For Recycling” Matters for Companies

Why “Design For Recycling” Matters for Companies Why Soft Plastics Are Problematic & Hard to Recycle

Why Soft Plastics Are Problematic & Hard to Recycle