Introduction

While the plastic crisis increases globally, recycling technology has become frontline in confronting mounting trash. Mechanical recycling has long led the way in managing plastic waste, but chemical recycling is now stepping in as a promising innovation—particularly for handling complex plastic materials that traditional methods can’t process, and for piloting new recycling approaches.

Chemical recycling can recycle plastic waste into its original molecular structure so it can be reused in high-value applications. Unlike traditional methods, it can handle mixed, multi-layered, or dirty plastic waste which cannot be treated mechanically. The process has intrigued policy makers, environmentalists, and chemical recycling companies across the world as a key driver of a circular economy.

This blog explores what plastic chemical recycling is, its key processes, how it contrasts with mechanical recycling, and why it is gaining momentum as an efficient solution in the future of sustainable waste management.

What is Chemical Recycling?

Chemical recycling of plastic, or advanced or molecular recycling, is a technique that depolymerizes plastic waste back into its chemical molecular building blocks. These building blocks are further employed to produce new plastic items, fuel, or raw materials.

Unlike mechanical recycling which grinds, washes and re-melts plastics, chemical recycling of plastic breaks down plastics at the molecular level. This means you can produce high quality, virgin equivalent plastics even from highly contaminated or multi layered waste.

Key features of chemical recycling of plastic are

- Molecular Recovery: Returns polymers to monomers or base chemicals.

- Contaminant Tolerant: Can handle coloured, mixed and non-recyclable waste.

- High Quality Output: Produces material suitable for food packaging and medical use.

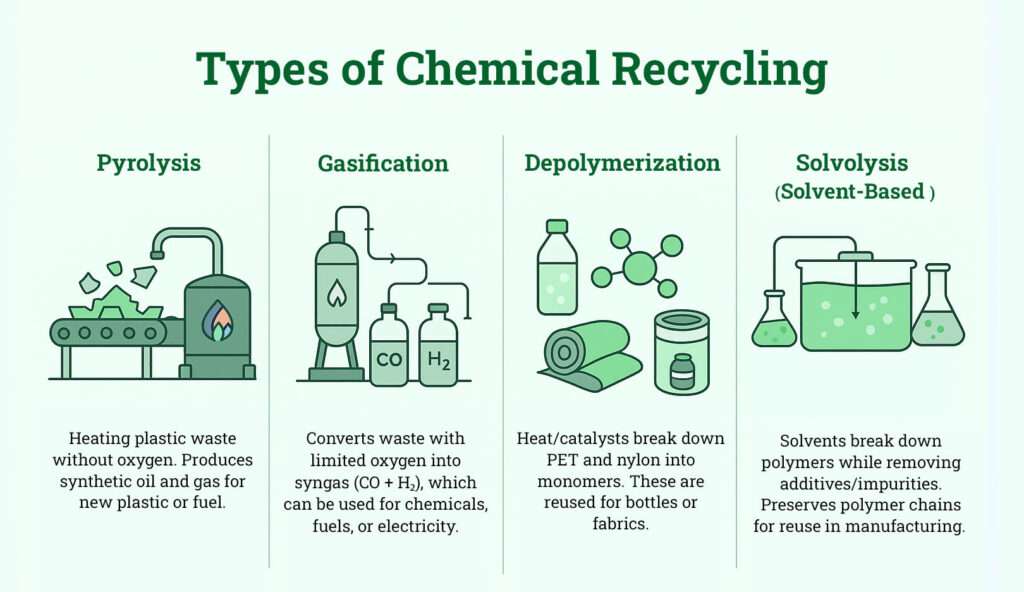

Types of Chemical Recycling

The chemical recycling process is classified based on initial materials and targeted end products. The fundamental methods are these:

1. Pyrolysis

- The process involves heating plastic waste without the presence of oxygen.

- Synthetic oil and gas outputs are processed which can then be transformed into usable fuels and new plastic materials.

( read more about the benefits of pyrolysis What is Pyrolysis of Plastic Waste? It’s Process & Benefits )

2. Gasification

- Through limited oxygen conditions waste converts into syngas which comprises carbon monoxide and hydrogen.

- The purification process transforms syngas into chemical products, fuel sources, or electrical power.

3. Depolymerization

- Heat or catalysts break down polymers into their monomers.

- The materials PET and nylon enable recycling processes to transform them into either new bottles or fabrics.

4. Solvolysis (Solvent-Based Recycling)

- Through the application of solvents, polymers break down while additives and impurities are simultaneously extracted.

- Maintains polymer chains for reintegration into manufacturing processes.

Chemical recycling process enables the creation of closed-loop systems for various plastics and their applications.

Chemical Recycling of Plastics: How Does It Work?

Here’s the step-by-step process of chemical waste recycling of plastics:

1. Collection & Sorting

Waste is collected from different sources; industry, municipal and post-consumer waste and sorted according to the plastic type.

2. Pre-treatment

Using shredders and other decontamination means, impurities are removed before the plastics are cleaned and this helps the chemical process to remain unhampered.

3. Chemical Breakdown

In this procedure (for example, pyrolysis or depolymerization), the plastics are heated or treated with special substances to tear their molecular structure apart.

4. Recovery of Chemical Product

The output – monomers, syngas, or oil – will be purified and stored.

5. Repolymerization or Reuse

Basically, these chemicals serve as feedstock to manufacture new polymers, and fuels, or they are used in making other chemicals.

Chemical waste recycling through these methods enables factories to separate the waste that is hard to be burned or disposed of in landfills and then reintroduce it to their supply chain.

What Are the Benefits of Chemical Recycling?

Different types of chemical recycling provides distinct benefits over traditional recycling:

- Works with difficult waste: Processes multi-layer film, color plastic, and soiled products.

- High-Purity Product: Produces material that is nearly virgin.

- Promotes Circular Economy: by converting waste into raw materials for production.

- Preserves Landfills: keeps plastics that are hard to recycle out of landfills.

- Energy Recovery: Some processes produce electricity or fuel that can be used.

These advantages of types of chemical recycling are crucial for material-intensive industries to achieve net-zero goals and lessen their reliance on virgin plastic made from fossil fuels. al for industries that rely heavily on materials to reach their net-zero targets and reduce their dependence on virgin plastics derived from fossil fuels.

How Does Chemical Recycling Contribute to a Circular Economy?

In contrast to conventional recycling, there are numerous benefits of chemical recycling. It doesn’t recycle—it rebuilds. Here’s how it fuels circularity:

• Product-to-Product Looping

This is basically allowing the waste to be the same product, for example, from a PET bottle to another PET bottle.

• Design-for-Recycling

It is a system that helps manufacturers to design their products which are suitable for recycling facilities.

• Value Chain Integration

This is a system that allows brands, recyclers, and chemical producers to collaborate together and co-develop sustainable solutions.

As one of the sustainability initiatives in India, the Extended Producer Responsibility (EPR) benefits of chemical recycling of plastics has significant potential in realizing waste to value and in mitigating our environmental impacts.

How is Chemical Recycling Different From Mechanical Recycling?

The chemical recycling vs mechanical recycling debate is often one of precision versus scale. Let’s breakdown the differences and have a look at the future of chemical recycling:

Criteria | Chemical Recycling | Mechanical Recycling |

Process Type | Breaks down molecules chemically | Physically melts and reshapes |

Waste Type Tolerance | Mixed/contaminated plastic-friendly | Needs clean, sorted plastics |

Output Quality | Virgin-equivalent plastic | Downcycled (lower-grade) material |

Energy Use | Higher (requires heat/catalysts) | Lower (simpler machinery) |

Environmental Impact | Potential emissions from processes | Less intensive, but limited scope |

Infrastructure | Emerging, high investment | Mature, widely adopted |

Mechanical and chemical recycling both have roles to play but the future of chemical recycling fills critical gaps left by mechanical limitations.

What Is the Future of Chemical Recycling?

The future of chemical recycling with favorable policy, growing demand for circular plastic, and quick technology advances, look for:

- Commercial Scale Plants: Scaling up pilot plants to full-scale operations.

- Policy Incentives: Subsidies and coverage under EPR mandates from governments.

- Integration with AI & Robotics: For sortation, pre-treatment, and quality inspection.

- Cross-Sector Collaboration: Between brands, chemical firms, and recyclers.

India itself will gain in that it is heading towards chemical recycling to counter its escalating plastic waste issues and expand circular economy efforts.

Conclusion

Chemical recycling is regarded as a transformative force in the global recycling sector. Inversely, the plastic mechanical recycling process is limited by the type and purity of the plastic, whereas the chemical recycling of plastics becomes a real option for hard-to-recycle waste streams. It allows the retrieval of plastics without degradation of performance, quality, or sustainability.

The chemical recycling companies, as they develop more innovations, and with the maturation of the legal framework, this technology will be incorporated into mechanical systems – not the other way around,presenting a holistic waste management model.

The industries that will invest in both systems from the very beginning will not only be able to comply with EPR norms but would also secure the future of their operations and increase the credibility of their ESG (Environment, Health, and Safety) certificate.

FAQ's

Why is chemical recycling important?

It can handle plastic types that mechanical recycling cannot, helping reduce landfill waste and produce high-quality recycled materials.

What are examples of chemical recycling?

Pyrolysis for fuel, depolymerization for PET bottles, and solvolysis for multilayer packaging are popular examples.

Is chemical recycling of plastic waste a safe process?

Yes, when properly regulated. With the right emissions control and safety protocols, it’s an environmentally safe method.

How does chemical recycling affect the environment?

It reduces plastic waste and supports circularity but must be managed carefully to prevent emissions from high-temperature processes.

Making recycled packaging the norm.

CITATIONS:

- Chemical recycling: tackling plastic waste | Shell Global. (n.d.). Shell Global. https://www.shell.com/business-customers/chemicals/chemical-recycling-tackling-plastic-waste.html

- Shah, H. H., Amin, M., Iqbal, A., Nadeem, I., Kalin, M., Soomar, A. M., & Galal, A. M. (2023). A review on gasification and pyrolysis of waste plastics. Frontiers in Chemistry, 10. https://doi.org/10.3389/fchem.2022.960894

- https://circulareconomy.europa.eu/platform/sites/default/files/2023-08/Chemical%20Recycling%20in%20Circular%20Perspective.pdf

What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling Why Burning Plastic Is Unsafe and Recycling Is the Better Solution

Why Burning Plastic Is Unsafe and Recycling Is the Better Solution Why “Design For Recycling” Matters for Companies

Why “Design For Recycling” Matters for Companies Why Soft Plastics Are Problematic & Hard to Recycle

Why Soft Plastics Are Problematic & Hard to Recycle