The global imperative for environmental responsibility is reshaping industries worldwide, and the packaging sector stands at the forefront of this transformation. Consumers are starting to pay closer attention to the ecological footprint of goods they buy, which in turn has led to the growing need for brands to be environmentally friendly. This increased sensitivity has taken sustainable packaging out of the fringe concern to become a mainstream requirement, spawning material and design innovation. Old fashioned packaging may use virgin plastics, whose manufacturing also burns through huge quantities of fossil fuels, fosters greenhouse gases, and results in very large quantities of waste that may not disappear off landfills during hundreds of years. The transition to recyclable and sustainable packaging materials, such as rPE (recycled polyethylene) and rPP (recycled polypropylene), provides a good approach to these issues. Sustainable packaging is made out of post consumer or post industrial waste thus completing a repetitive cycle in a thousand year old economy and significantly lowering the need to make more plastic products. Brands are coming to the understanding that going rPE and rPP is not only a matter of compliance or reducing adverse effects on the environment but also creating a better brand image, consumer loyalty, and a healthier planet. This operational shift to recycled material is a decade-long commitment to environmental stewardship that puts the companies in the lead in the sprint to a decidedly circular future.

Introduction

The reduction of environmental impact starts with the conscious decision in all developments of products (particularly packaging). Eco-friendly packaging is not a fashion or a fad anymore; it is one of the main demands by environmentally aware consumers and an inseparable part of corporate social responsibility. The uptake of materials such as rPE and rPP is a straightforward response to the critical demand to build a green future.

What is Sustainable Packaging & Why is it Important?

Sustainable packaging is defined as the packaging that has the least environmental impact during its lifetime, including the sourcing and disposal or recycling of raw materials. A holistic approach combining design with choice of material, manufacturing, and end-of-life management that matches the principles of a circular economy. The significance of eco-friendly packaging and sustainability hardly needs to be exaggerated. Eco-friendly packaging lessens the use of virgin resources, uses less energy, less greenhouse emissions and less waste in landfills, a direct fight against environmental degradation.

- Reduces Carbon Footprint: Manufacturing with recycled content significantly lowers energy use and associated emissions.

- Saves Resources: Reduces the need to create new plastics with fossil fuels.

- Minimizes Waste: Keeps valuable materials out of landfills and oceans.

- Enhanced Brand Reputation: Appeals to environmentally conscious consumers and stakeholders.

Supports Circular Economy: Favors a process in which the materials are extended in service as long as possible.

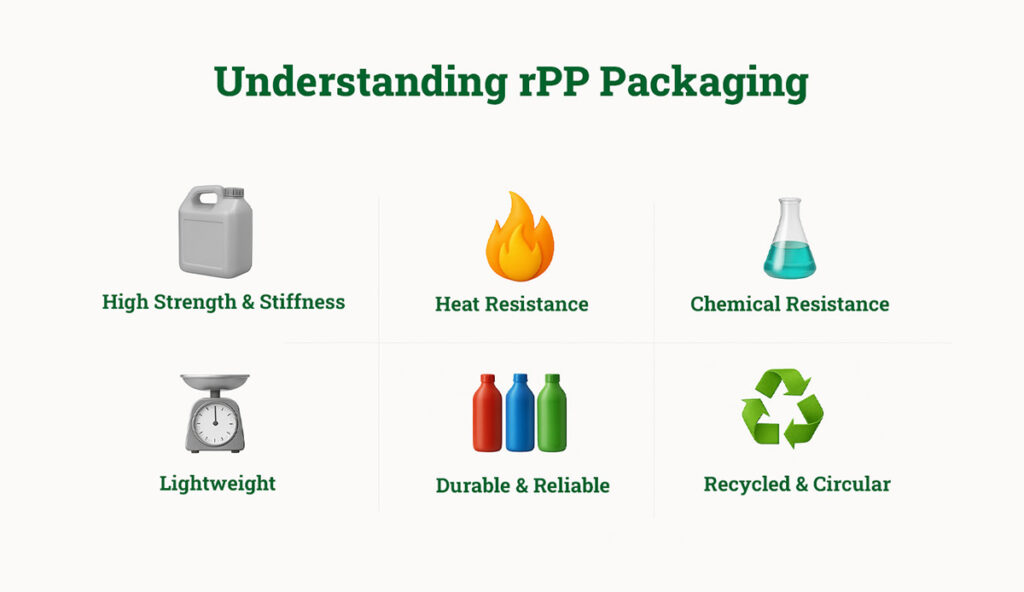

Understanding rPP Packaging

Recycled Polypropylene (rPP) packaging is a highly versatile and strong type of recycled plastic that is a post-industrial and post-consumer waste. This content is well gathered, refined, washed and segregated to form quality pellets. The packaging and sustainability are greatly enhanced when rPP is used and exhibits similar characteristics to virgin PP, thus can be easily utilized in a wide range of applications without having a significant impact on the pack performance.Increased attention to packaging and sustainability also provides brands with an opportunity to safely transition to recycled materials. This is an important strategic step towards circularity both to the environment and to the company regarding packaging and sustainability.

- High Strength and Stiffness: Best for heavy-duty containers, caps and closures.

- Excellent Heat Resistance: Can be used for microwaveable and hot-fill applications

- Good Chemical Resistance: Protects contents from many chemicals.

- Lightweight: Decreases transportation costs and resulting emissions

- Versatile: As they can be made in natural or in multiple custom colors.

Understanding rPE Packaging

Polyethylene (rPE) is available in two forms, i.e., rHDPE (recycled High-Density Polyethylene) and rLDPE (recycled Low-Density Polyethylene). In the sustainability of packaging both are recycled with an exceptionally wide variety of post-consumer plastics, including milk jugs, detergent bottles (HDPE), and plastic films or so-called grocery bags (LDPE). When using rPE as a packaging material you are making a huge difference in the sustainability of the packaging process by including materials that would have contributed to the waste. It is our commitment to sustainability of packaging that enables us to keep valuable resources within the loop.

- rHDPE (HDPE beginning with R) – recycled High-Density Polyethylene.

- Durability & Rigidity: Ideal for bottles, jugs, and other rigid containers.

- Impact Resistance: does not lose strength upon being subjected to tension.

- Good Moisture Barrier: Prevents external moisture damage to products

- rLDPE(Recycled Low Density Polyethylene):

- Versatility: Great for films, bags, and squeeze bottles.

- Puncture Resistance: Delivers strong defense to flexible applications

- Good Clarity (when processed properly): Suitable for packaging where product visibility is desired.

Why rPP & rPE matters in packaging?

The importance of rPP and rPE is being recognized and emphasized by the increasing focus on packaging and sustainability. These packaging materials are not just the alternatives, they are the backbone of truly circular packaging. For the brands integrating rPP packaging and rPE packaging, a conscious move away from virgin fossil-fuel-based plastics that actively reduces their environmental impact and takes a direct step towards a more responsible production model.

Reasons why brands are switching towards rPP & rPE for sustainable packaging

The benefits of a compelling combination of environmental, economic, and reputational advantages are driving fast uptake of rPP packaging and rPE packaging by brands:

- Consumer Demand: There is also no doubt about the preference to buy something sustainable.

- Regulatory Compliance: Meeting EPR (Extended Producer Responsibility) mandates and other environmental regulations.

- Less Carbon Footprint: A lot less energy was used and greenhouse gas emissions were significantly lower than the virgin production of plastic.

- Resource Conservation: Less reliance on finite fossil fuels for plastic manufacturing.

- Strong Brand Image: Communicates a true desire to act in a sustainable way, which creates trust and loyalty.

- Cost-Effectiveness (Long-term): Stabilizes material costs and reduces waste disposal expenses.

- Performance Parity: Recycling technologies are advanced so as to result in rPE and rPP attaining the functional performance of virgin plastics.

What are some Examples of Sustainable Packaging?

Sustainable packaging with rPP and rPE examples is already growing quickly in different fields. Some examples are

- Food & Beverage: Yogurt cups (rPP), milk jugs (rHDPE), beverage closures (rPP).

- Personal Care: Shampoo bottles (rHDPE), lotion containers (rPP), cosmetic jar lids (rPP).

- Household Cleaners: Detergent bottles (rHDPE), spray bottle components (rPP).

- Automotive: Interior components, fluid containers (rPP, rHDPE).

- Consumer Goods: storage bins (rPP, rHDPE), electronic casing (rPP).

These instances demonstrate that recyclable product packaging is taking a new shape into routine product packaging.

How does Banyan Nation’s rPP & rPE help in the sustainability of packaging?

We have been leading in offering rPP packaging and rPE packaging solutions at Banyan Nation. Banyan Nation’s proprietary hot wash and USFDA-approved deodorization technologies work in tandem to produce virgin-like high-quality, food-grade recycled plastics tailored to India’s waste streams. This gives brands the confidence to incorporate recycled contents within their main packaging without affecting their packing. By providing fully traceable materials that are compliant, we are helping brands reach their sustainable packaging targets and gain momentum on the path to a really circular packaging future.

Conclusion – A Sustainable Future with rPP & rPE Packaging

The transition to the rPE and rPP packaging (not a trend but an imperative change for the packaging industry ) is something that definitely needs to be addressed. Companies which adopt these materials are not just fulfilling the consumers needs and regulatory demands, but they are also helping to build a circular economy. Banyan Nation is happy to be part of this process, and its high-quality recycled materials can help make sustainable packaging impactful. Sustainable packaging is undoubtedly its future and rPE and rPP are spearheading it.

FAQ's

What are the 7 R's of sustainable packaging?

The 7 R’s typically include: Rethink, Reduce, Reuse, Repair, Recycle, Recover, and Refuse. These principles guide the design of best recyclable packaging and implementation of sustainable packaging examples.

What are the 4 pillars of sustainability strategy?

The four pillars of sustainability strategy are often referred to as Environmental, Economic, Social, and Governance (ESG). Effective circular packaging contributes positively to all these pillars.

Why is sustainable packaging better?

Sustainable packaging is better because it reduces environmental pollution, conserves natural resources, minimizes carbon footprint, and enhances corporate social responsibility, leading to a healthier planet and stronger brands with recyclable product packaging.

Making recycled packaging the norm.

CITATIONS:

- Swiss Pack. (2024, October 14). Why companies are switching towards sustainable packaging. Retrieved from swisspack.co.in

- United States Environmental Protection Agency (EPA). (n.d.). Recycling Basics and Benefits. Retrieved from epa.gov

- The World Bank. (2018). What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Retrieved from worldbank.org

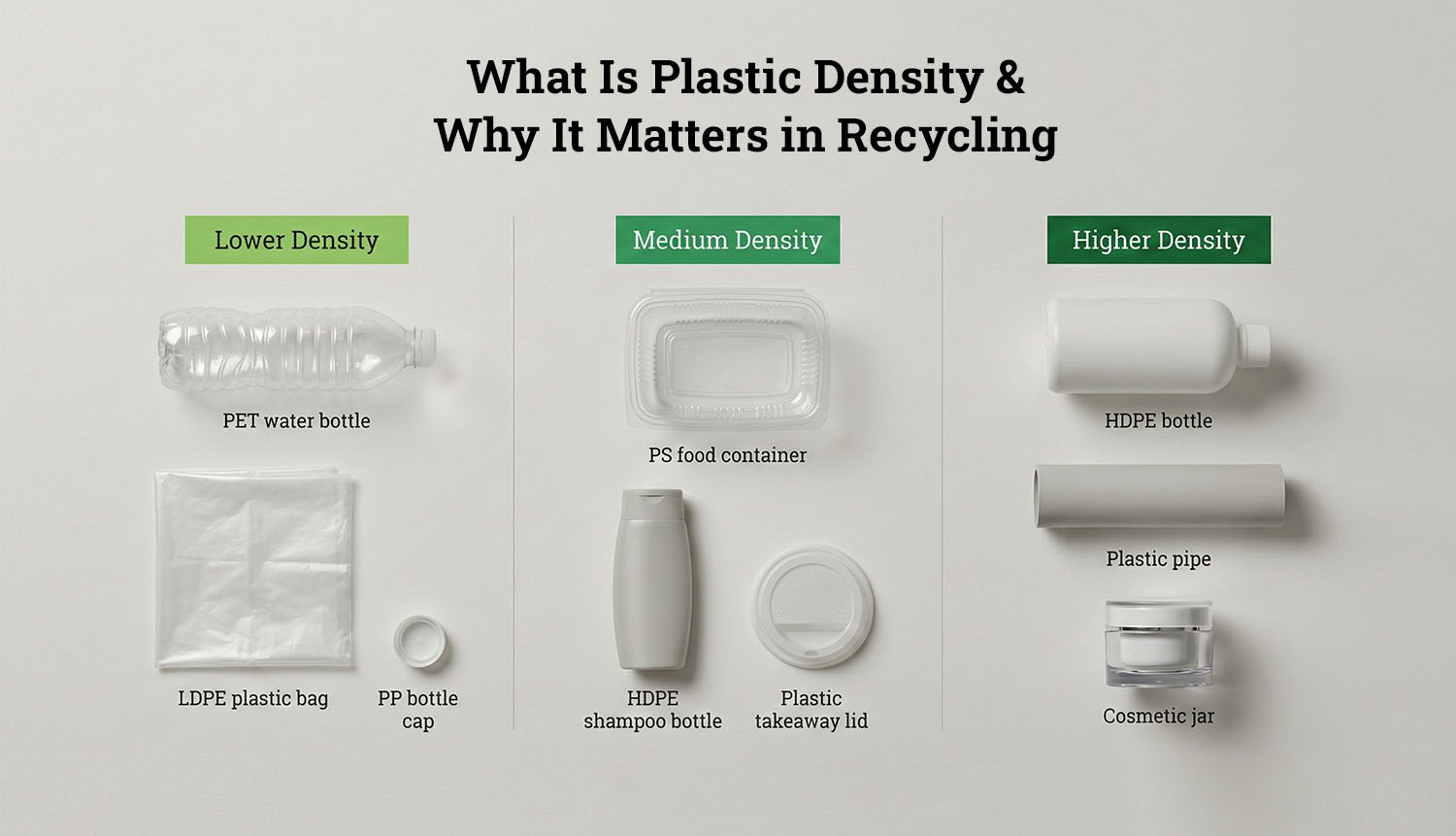

What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling Why Burning Plastic Is Unsafe and Recycling Is the Better Solution

Why Burning Plastic Is Unsafe and Recycling Is the Better Solution Why “Design For Recycling” Matters for Companies

Why “Design For Recycling” Matters for Companies Why Soft Plastics Are Problematic & Hard to Recycle

Why Soft Plastics Are Problematic & Hard to Recycle