With the fast changing world of sustainable manufacturing, the granulation process becomes the most important link between the large masses of plastic waste and raw materials of high quality. Simply put, granulation is a mechanical size-reduction method which converts plastic scrap into reworkable and easy to manage small, uniform granules or pellets or granules. The importance of this phase is that most of the modern manufacturing machines like injection molding machine and extruder are set to handle standardized feedstocks and not the heterogeneous wastes. In the absence of efficient granulation, the recycling process would have been incomplete since the dissimilar forms of bottles, crates, and films would not fit in the production lines uniformly. Through recycling on an industrial level, it is not all about chopping plastic, but a precision operation which may rely on high-speed rotating blades and screening systems in order to keep every particle to a certain size criteria, which is generally in the size range of 3mm to 12mm. It is this consistency that enables recyclers, such as Banyan Nation, to manufacture Better Plastic – a resin made out of recycled material yet working like a virgin resin. Granulation also contributes to a significant improvement in the whole recovery chain by decreasing the amount of plastic waste held and increasing the surface area of plastic waste to be cleaned and melted. This process should be mastered as any brand that aims at adapting to a more circular economy in 2026 to include post-consumer recycled (PCR) content in their main packaging without compromising the quality or performance of their products.

Introduction

With the transition of industries to the models of the circle, the technical peculiarities of the material recovery become a competitive advantage. What is granulation in a contemporary recycling plant? It is the heartbeat of the plant as the various wastes become a universal language of pellets which manufacturers can really utilize. This transformation has to take place before a plastic bottle can be transformed into a new detergent container. The stage of granulation guarantees:

- Feeding Stability: Eliminates jams in downstream manufacturing apparatus.

- Cleaning Efficiency: More area available to clean up dirt and contaminants.

- Logistical Ease: Makes waste less dense which makes it less expensive to move around.

What Is Granulation?

To find out the answer to the question what is granulation process in detail, it is necessary to take it as a sort of industrial digestion. It is the process in which the hard or soft plastic is converted into a controllable form.

When individuals enquire what is granulation specifically, they are perhaps referring to the secondary reduction of size. A shredder can cut up a huge auto bumper into chunks the size of a hand; a granulator cuts up such chunks and cuts them into accurate, rice-sized particles. It is this detail that makes plastic granulation a high precision recycling instrument.

Understanding Plastic Granulation

The science of what is the granulation or more specifically, plastic granulation is the balancing between the motor torque and speed of the blade. A granulator has high speed sharp knives that ensure the material is cut rather than crushed as it is done in a shredder where the high speed of the shredder provides low torque to the blades.

The main factors of plastic granulation system are:

- The Rotor: This is the central spinning shaft onto which the cutting knives are attached.

- Bed Knives: Stationary knives that act on the rotor to cut the plastic.

- The Screen: This is an open plate made of metal with holes strategically placed to restrict the passage of anything other than the appropriate size of granules.

- The Hopeper: This is where the plastic garbage that has been sorted is fed into the machine.

What Is the Process of Plastic Granulation?

What is the granulation, specifically the plastic granulation process is a multi-stage process that is intended to achieve the greatest possible purity and uniformity.It is uncommon as it is a component of a bigger mechanical recycling line. The following is the general flow of the plastic granulation process:

Feeding

Pre-shredded and sorted plastic gets into the cutting chamber.

Shearing

The rotor blades move at a high speed through the bed knives that are kept still cutting the plastic repeatedly.

Sizing

The material is bounced in the chamber until it becomes small enough to pass through the screen.

Extraction

A vacuum or air system is used to continue to pull away the completed granulation output either to a storage silo or in the direction of the washing line.

Benefits of Granulation in Plastic Recycling

The granulation in plastic recycling has a number of structural and economic benefits to both the recycle and the final user. In the absence of this, the recycled plastic would not have a high quality to be used in high-end processes.

Superior Uniformity

Gives a uniform flake size, which is imperative to an even melting in an extruder.

Better Washing

Smaller granules enable the water and cleaners to reach every part of the surface cleaning more odors and stickers compared to larger pieces.

Increased Bulk Density

In recycling, granulation enables you to fit a substantial amount of material in a shipping container or storage silo, resulting in the optimization of logistics.

Energy Savings

Uniform granules are melting faster and more evenly, which saves on the energy required to complete the last step of pelletizing.

How Does Plastic Granulation Enhance Recycling Efforts?

The effect of granulation in recycling of plastic is most apparent in the closed-loop production of consumer products. Making high quality regrind, through granulation in recycling of plastics has helped brands substitute 30, 50 or even 100 percent of their virgin plastic content with recycled material. This is what allows bottle-to-bottle recycling.

Recyclers have a chance to set the output size to the exact size to ensure that the final resin is of the necessary size needed by the high-speed production lines in terms of melt-flow index. This is the technical reliability that helps to promote more companies to invest in sustainable packaging.

How Does Granulation Improve Plastic Waste Management?

On a macro level, granulation in plastic recycling is an instrument of mass loss and value reimbursement. Volume is the bane in the municipal waste management. The waste is granulated at the source or at a regional center and the carbon footprint of waste transportation is reduced. Moreover, it is in granulation which can be sorted automatizing. Optical sorters and NIR (Near-Infrared) sensors are able to pass small and uniform flakes more precisely compared to bulky and distorted bottles. This accuracy increases recovery, reduces landfill material and has a direct effect on the sustainability of the world.

Conclusion

Granulation is a must in the process of transforming the waste into the rich. We transform the chaotic, post-consumer plastic by refining it into a standardized granule, and open the possibilities of a truly sustainable economy. The plastic granulation at a local plant or the modernized systems of Better Plastic at Banyan Nation this technology makes plastic a resource to be utilized as opposed to a contaminant. Granted, as we move into the future, the accuracy and efficacy of the granulation process will remain the gold standard of high performance recycling.

FAQ's

What Types of Plastics Are Suitable for Granulation?

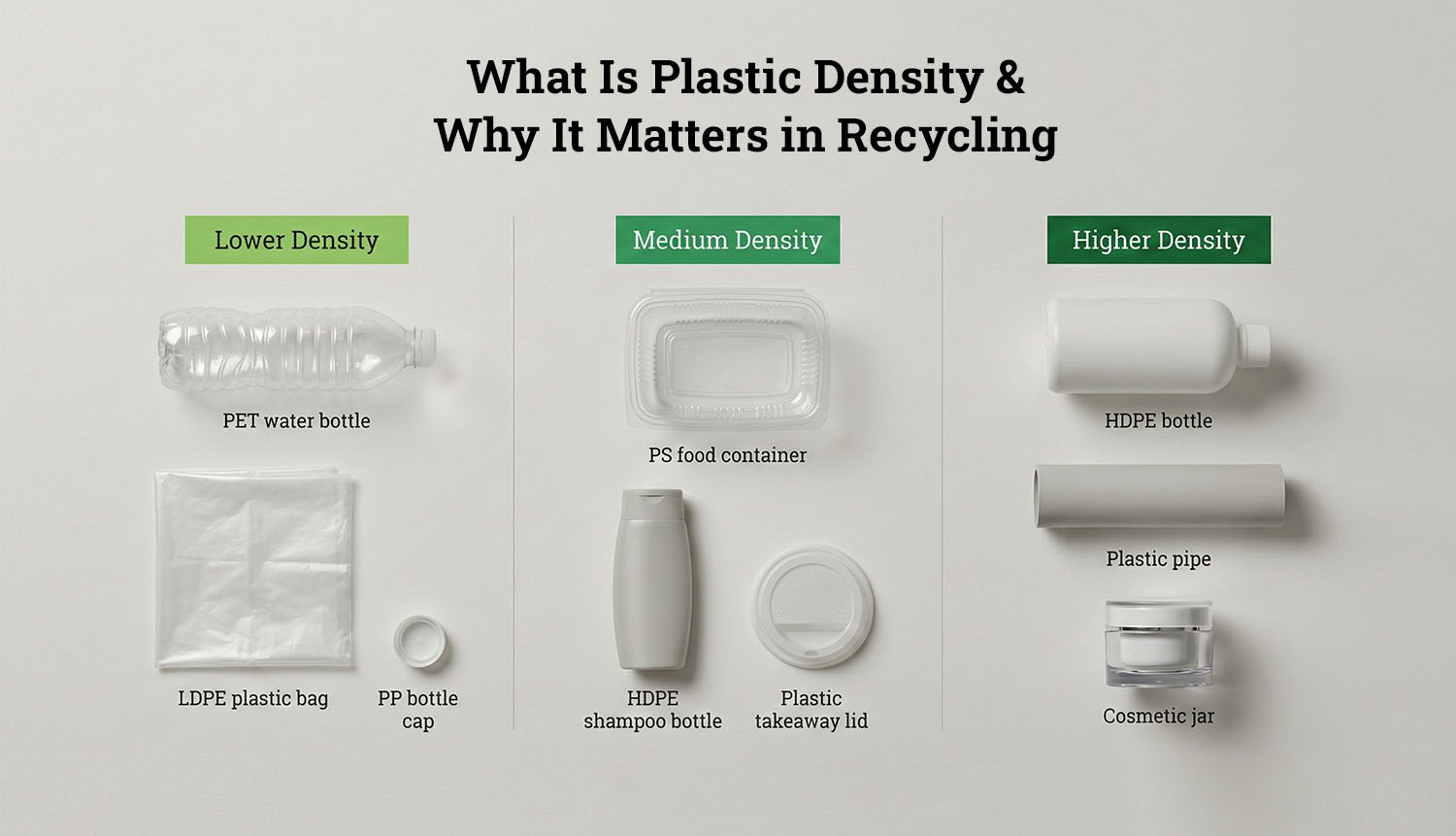

Almost all thermoplastics can be granulated, including HDPE Plastic (milk jugs), Polypropylene Plastic (bottle caps), PET (beverage bottles), and LDPE Plastic (flexible films). However, the blade design must be tailored to the material’s hardness, soft films require a “scissor-cut” while rigid crates need a “heavy-duty” rotor.

Why Is Granulation Important in Plastic Recycling?

It is the only way to create a uniform material that can be consistently fed into manufacturing machinery. It also maximizes the surface area for cleaning, which is essential for removing the odors and contaminants found in post-consumer waste.

How Does Plastic Granulation Support Sustainability?

By turning waste into a high-quality raw material, it reduces the need for virgin plastic produced from fossil fuels. It also makes recycling more economically viable by reducing transportation costs and improving the quality of the final product.

What Is the Difference Between Plastic Granulation and Shredding?

A shredder is a “primary” reducer that uses low speed and high torque to break down bulky items into rough chunks. A granulator is a “secondary” sizing machine that uses high speed to produce fine, uniform flakes suitable for direct manufacturing.

Making recycled packaging the norm.

CITATIONS:

- Hebei Fangtai Plastic Machinery. What Is the Granulation Process? Retrieved from: https://www.fangtaiplasticmachine.com/

- Conair Group. The Basic Differences Between Plastics Granulators and Shredders.

- Pashupati Group. (2025). Recycled HDPE Granules: Turning Waste into Productive Material.

What Is Granulation in Plastic Recycling?

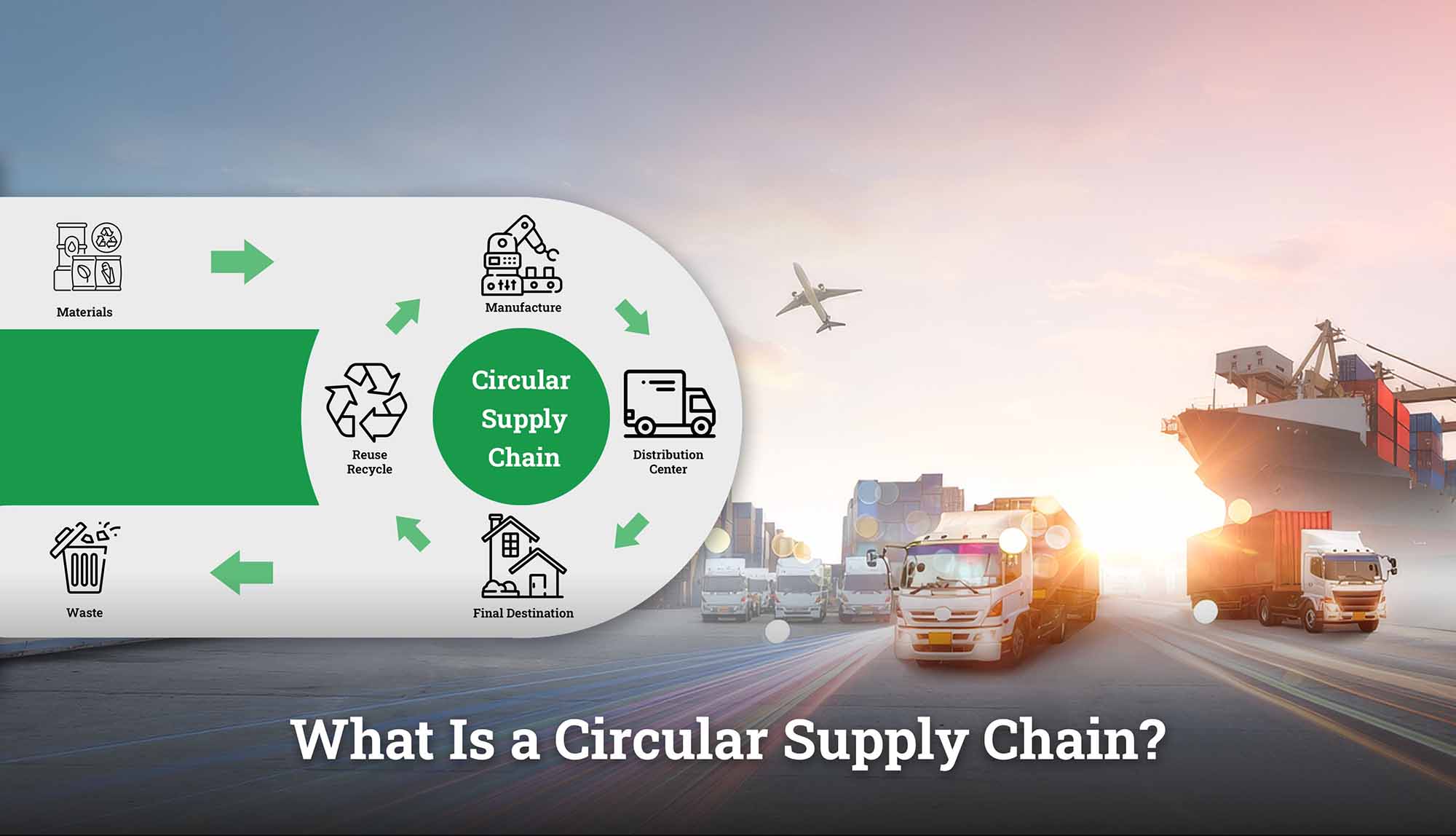

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India? What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling