The presence of plastic packaging in our everyday life as convenient as it is has posed an intricate and daunting waste problem. Whereas the PET bottles and HDPE containers that represent a relatively mature and effective recycling stream are relatively rigid and therefore relatively easy to recycle, the thinner and more flexible containers that make up the soft plastics or plastic film present an even greater dilemma. These are materials that include multi-layered snack wrappers down to single-use plastic carry bags, and they constitute a significant part of plastic waste, and are infamously hard to process. The major problem is not only collecting these lightweight and low-density materials but also the technological nightmare that they cause in Material Recovery Facilities (MRFs). Incorrectly thrown soft plastic causes contamination of bales of more valuable rigid materials and, most importantly, clogs the highly automated sorting equipment, resulting in operational stoppage, higher maintenance expenses, and even endangering workers. This entanglement problem implies that a system may be open to soft plastic but due to the higher costs and risks, the environmental advantage is usually offset. Moreover, many of these soft plastic materials including multi-layered packaging (MLP) consist of a mixture of various polymers or layers of such materials as aluminum foil, and it is therefore economically not possible to mechanically separate them. This technical intricacy is precisely the root cause of why much of this spillage stream usually finds its way into landfills where it can be leached to toxins and degenerate into enduring microplastics.

Introduction

Handling the crisis of soft plastics is the key to every nation interested in environmental sustainability and the circular economy, and especially in developing countries such as India where flexible packaging is extremely popular. The lightness and elasticity that enable soft plastics to make the best packaging materials such as offering oxygen protection, shielding, and being sealable are what make them a nightmare to the standard recycling systems. The inability to isolate the various types of polymers, high surface-to-volume ratio, which contaminates more, and the tendency of tangling in machinery are some of the reasons why most soft plastics have rarely been involved in mainstream recycling in the past. The inability to reuse and manage these materials effectively is a tremendous waste of resources and a significant source of environmental pollution, and there is the acute necessity to find highly specialized and technologically advanced ways to manage soft plastics.

What are Soft Plastics?

Flexible plastics or soft plastics, alternatively called soft plastics, are lightweight materials which can easily be scrunched or stretched. They are mostly composed of such polymers as Low-Density Polyethylene (LDPE, RIC #4) and Linear Low-Density Polyethylene (LLDPE).

Some examples of what are soft plastics for recycling are:

- Plastic carry bags

- Bread packets and vegetable wrappings

- Bubble wrap and plastic shipping envelopes

- Liners of cereal boxes and cling film used in the kitchen

- Covering of product (e.g. toilet paper or bottled water around it)

What is soft plastic recycling?

Soft plastic recycling entails the process of gathering, sorting, and reprocessing these soft plastic resources into useful raw materials, which are usually recycled pellets of low-density polyethylene (rLDPE) into moldable raw materials, such as composite decking, outdoor furniture or new film packaging. This necessitates special collection programs since they are not normally taken in curbside bins.

How Does Soft Plastic Recycling Collection Work?

The recycling of the soft plastics needs a distinct collection method because of the problem of the jamming of the machinery. Soft plastics recycling is normally done through a centralized deposit or drop-off program as opposed to mixed curbside collection.

Retailer Drop-Off

This is a key component of many successful recycling programs of soft plastics where a critical element is the collection point that is located at large supermarkets and retail chains. At the entrance of the store, consumers will place their clean and dry soft plastics in special bins.

Dedicated Industrial Collection

In the case of businesses (e.g., warehouses, manufacturers), a special type of soft plastic recycling is provided as a business service that collects a large amount of comparatively clean plastic film, pallet wrap, and packaging over wrap.

Segregation by Informal Sector

In the Indian situation, the informal sector is an important segment of the first collection and hand-sorting of the different plastic films, but quality and purity may be a major issue when it comes to further processing.

This separated assortment is the necessary initial move, which enables the successful recycling of soft plastics.

How to Manage Soft Plastics?

Both businesses and consumers should be willing to work together on the management of soft plastics.

Consumer Action

The consumers should know that home bins are usually unable to recycle soft plastics. They need to be picked up under different categories, cleaned and dry and handed over at the specific recycling areas of soft plastics or handed over to the specific soft plastic recycling centre of business collection initiatives where applicable.

Brand Design

The companies should follow the guideline of Design to Recycling, that is, to avoid an unjustified mixture of polymers or materials (such as multi-layered packaging), it is needed to make sure that the material can be processed.

Business Responsibility

In Extended Producer Responsibility (EPR) requirements, those companies producing soft plastics are to finance their collection, transportation, and processing. To meet their requirements of recycling of soft plastics, they should collaborate with recyclers who can handle this difficult stream.

What are the Challenges of Recycling Soft Plastics?

The challenge of obtaining good-quality recycling soft plastics is due to a number of technical and logistical challenges:

Pollution

Soft plastics can be contaminated by food residues as they are in direct contact with food (e.g., bread bags), snack wrappers, etc.), which reduces the quality of the final recycled product and may pollute individual batches.

Low Density and High Volume

It is light and bulky, thus, it is economically inefficient to collect, store, and transport it than the dense and rigid plastics.

Polymer Complexity (Multi-Layered Packaging)

Polymer films that are multi-layered plastic (consisting of other plastic types (e.g., LDPE and PET) or layers of aluminum) are used in many soft plastics, especially food pouches and crisp packets. These layers are not easily separable mechanically and it makes recycling soft plastics a hard task or even an impossibility using the traditional methods.

Machinery Entanglement

Due to the aforementioned, combining soft plastics with rigid products at the MRFs creates a problem with operations, and frequently all the combined stream flows to the landfills.

Ways to Tackle Soft Plastic Recycling

It will take both systems and technological innovation to tackle the obstacle against recycling soft plastics.

Chemical Recycling Technologies

Pyrolysis Chemical Recycling (also called pyrolysis) provides a method of converting complex and multi-layered soft plastics into their chemical building blocks (oils or monomers). This avoids the mechanical separation process and is capable of treating a highly polluted stream.

Niche Recycling

Firms such as Banyan Nation are creating technologies that will selectively recycle and purify certain polyolefins, such as rLDPE, generated using stream soft plastics. Recycled Low-Density Polyethylene (rLDPE) is made by using select post-consumer streams, and can be recycled into new flexible packaging or products such as films, stretch wrap and other high-quality soft plastics, which is great business recycling of plastic.

Mandatory Collection Networks

Introducing universal, countrywide drop-off systems, possibly subsidized by EPR and funded by the government, to direct huge and walled-off volumes of soft plastics to specific processors, omitting the troubled MRF phase.

Design to Mono-Materiality

Industry Cooperation to redirect the design of packaging materials to single-polymer soft plastics (mono-materials) that are more readily rerecycled.

Conclusion

The soft plastics problem is a micro-system of the overall intricacy of plastic waste management. It requires more advanced solutions than mere collection. Through the use of advanced recycling technologies, such as that developed by Banyan Nation to clean and recycle more difficult polyolefins such as rLDPE and by introducing effective and segregated business model collection through soft plastic recycling, India can shift its status about the soft plastic problem to one that genuinely recycles plastic material in this important packaging sector.

FAQ's

Which soft plastics can be recycled?

All soft, clean, dry plastic, which stretches on pulling, can usually be recycled using special drop-off programs. They are grocery bags, bread bags, dry cleaning wrap and product overwrap.

What is made from recycled soft plastic?

The recycled soft plastic (rLDPE) can be recycled in the non-food contact category, such as composite lumber to be used as an outdoor decking material, garden furniture, construction products, rubbish bin liners, non-food plastic film and packaging.

What are examples of soft plastic recycling?

The retail based drop-off programs of supermarkets in the UK and Australia are good examples of soft plastic recycling for business, or business-specific soft plastic recycling, which gathers plastic film and pallet wrap as commercially used in the warehouses.

Making recycled packaging the norm.

CITATIONS:

- Clear Drop SPC. (2025).

Soft Plastic Recycling: Key U.S. Challenges & Home Solutions.

Retrieved from:

https://onecleardrop.com/blogs/news/soft-plastic-recycling-key-challenges-and-solutions - Co-op. (2025).

Soft Plastic Recycling – Clean it. Scrunch it. Co-op it.

Retrieved from: https://www.coop.co.uk/environment/soft-plastics - Plastics Europe. (2025).

Recycling technologies: Advanced Recycling.

Retrieved from: https://plasticseurope.org/sustainability/circularity/recycling/recycling-technologies/

What Is Granulation in Plastic Recycling?

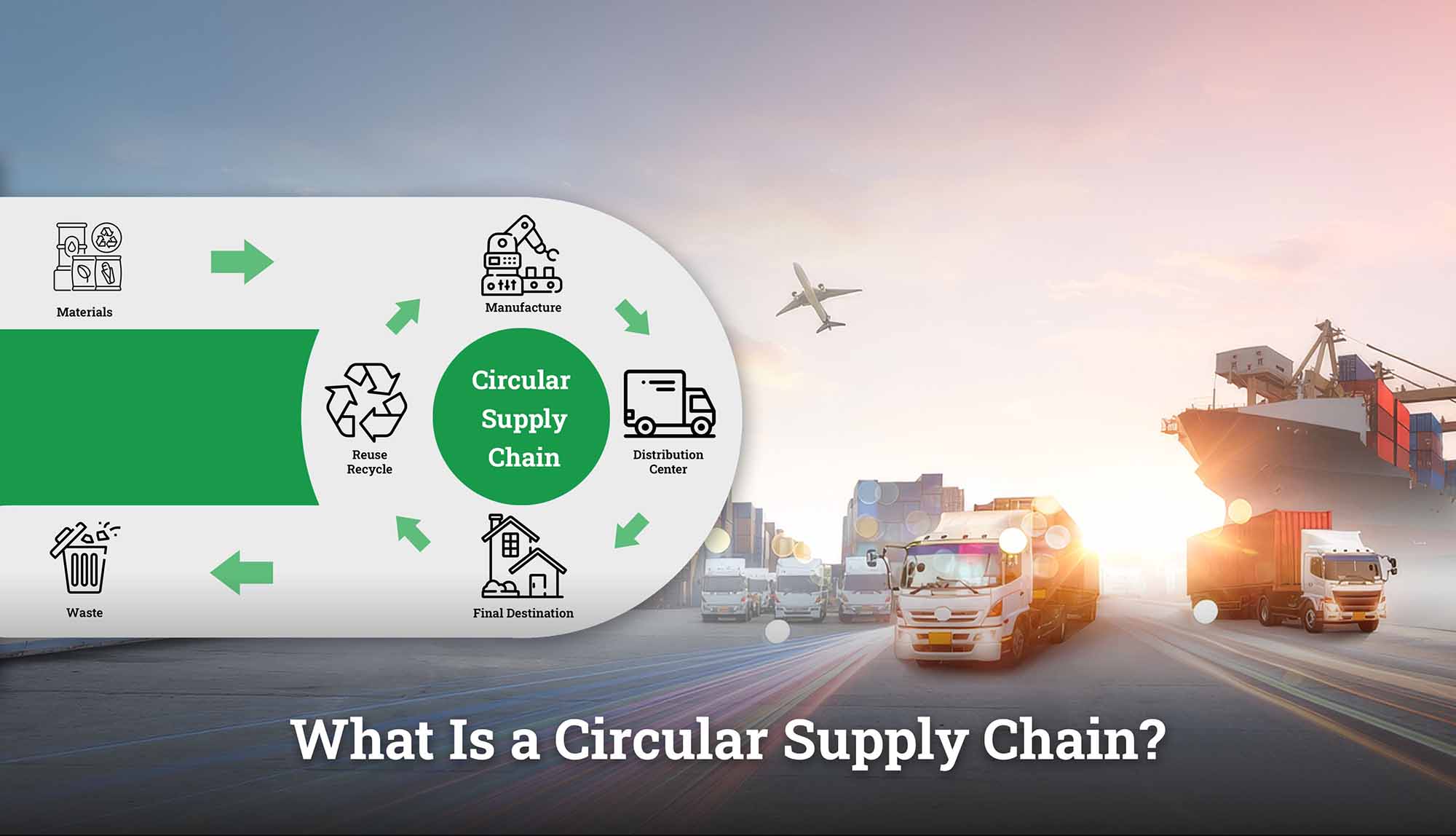

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India? What Is Plastic Density & Why It Matters in Recycling

What Is Plastic Density & Why It Matters in Recycling How Waste Pickers Play a Crucial Role in Recycling

How Waste Pickers Play a Crucial Role in Recycling